Muna ba da ƙwararrun sabis na walda na PCBA don tabbatar da cewa samfuran ku na lantarki suna cikin mafi kyawun matakin inganci da aiki.

Me yasa zabar sabis ɗin walda na PCBA ɗin mu?

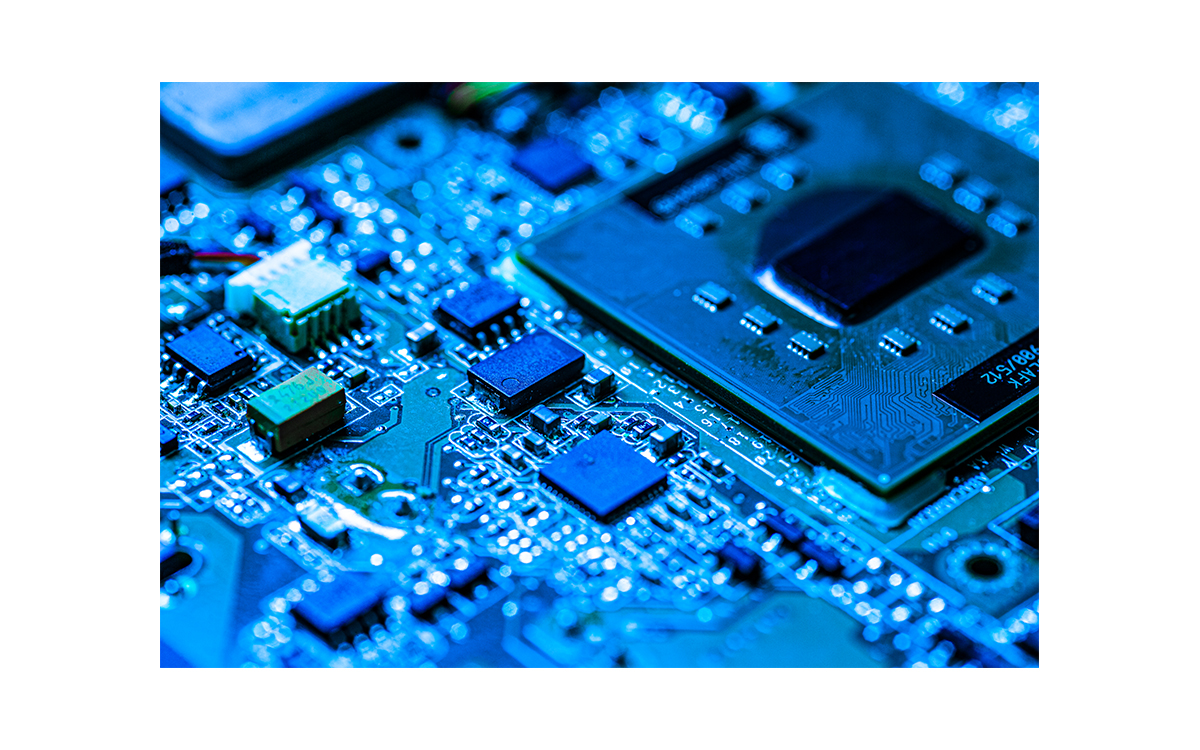

●Fasaha mai ingancin walda: Muna da ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun hanyoyin walda da dabaru daban-daban, gami da fasahar ɗorawa saman dutse (SMT) da fasahar toshewa (THT).

Ko yana da wani karamin surface Dutsen bangaren ko wani babban plug-in bangaren, za mu iya kammala waldi tsari daidai da nagartacce.

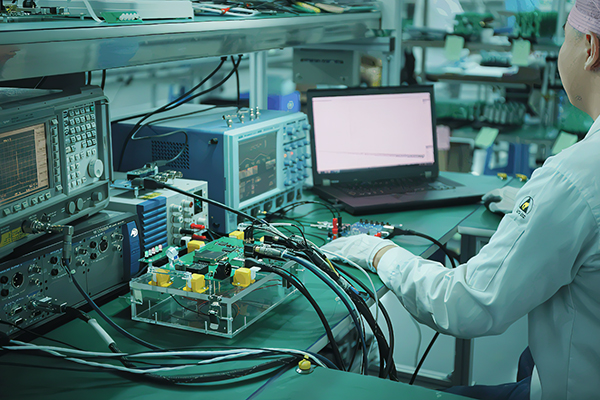

●Tsananin ingancin kulawa: Muna aiwatar da ingantaccen tsarin kula da inganci don tabbatar da cewa kowane tsarin walda ya dace da ka'idodin inganci.

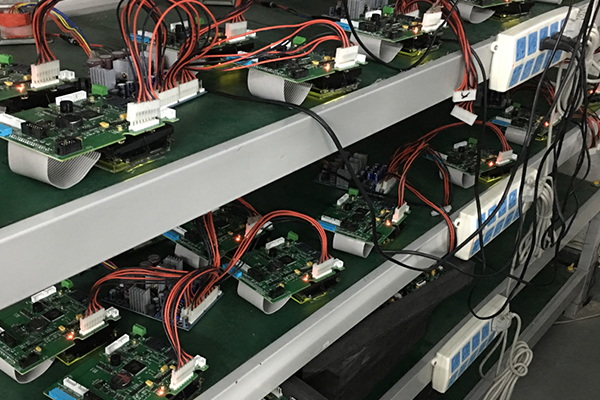

Muna amfani da na'urorin gwaji na ci gaba da hanyoyin don gudanar da cikakken gwaji da tabbatar da haɗin haɗin gwiwar solder, ingancin walda da ingantaccen shigarwa na abubuwan haɗin gwiwa don tabbatar da amincin samfura da aiki.

●Musamman mafita: Za mu iya samar da musamman PCBA waldi mafita bisa ga abokin ciniki bukatun.

Muna aiki tare da abokan cinikinmu don fahimtar ƙayyadaddun buƙatun su da tsammanin su, da kuma samar da shawarwari masu dacewa da tallafin fasaha don cimma mafi kyawun sakamakon walda.

Kafin Production

A cikin Production

Bayan Production

Binciken bayanai

Inganta fayil

Shigar BOMAikace-aikacen Siyarwa

Tabbacin Samfurin (Injinin Aikin, Abokin Ciniki) Ƙaddamarwar Gwaji, Samar da Jama'a (Mai injiniyan aikin yana bin dukkan tsari)

Takaitacciyar aikin (Yi rikodin fayil ɗin don maimaita umarni) Biyan abokin ciniki (sabis na bayan-tallace-tallace)

Tsaya Daya Tsaya Pcba Processing Da Manufacturing Sabis

Layin SMT

AOI

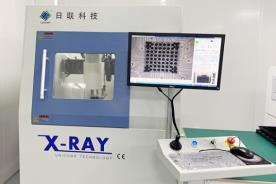

X-RAY

Sake dawo da gubar mara guba

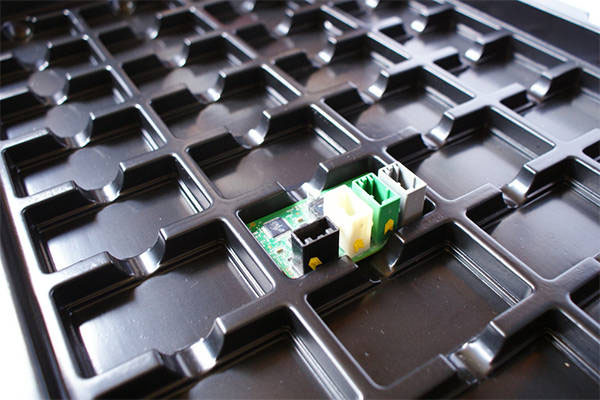

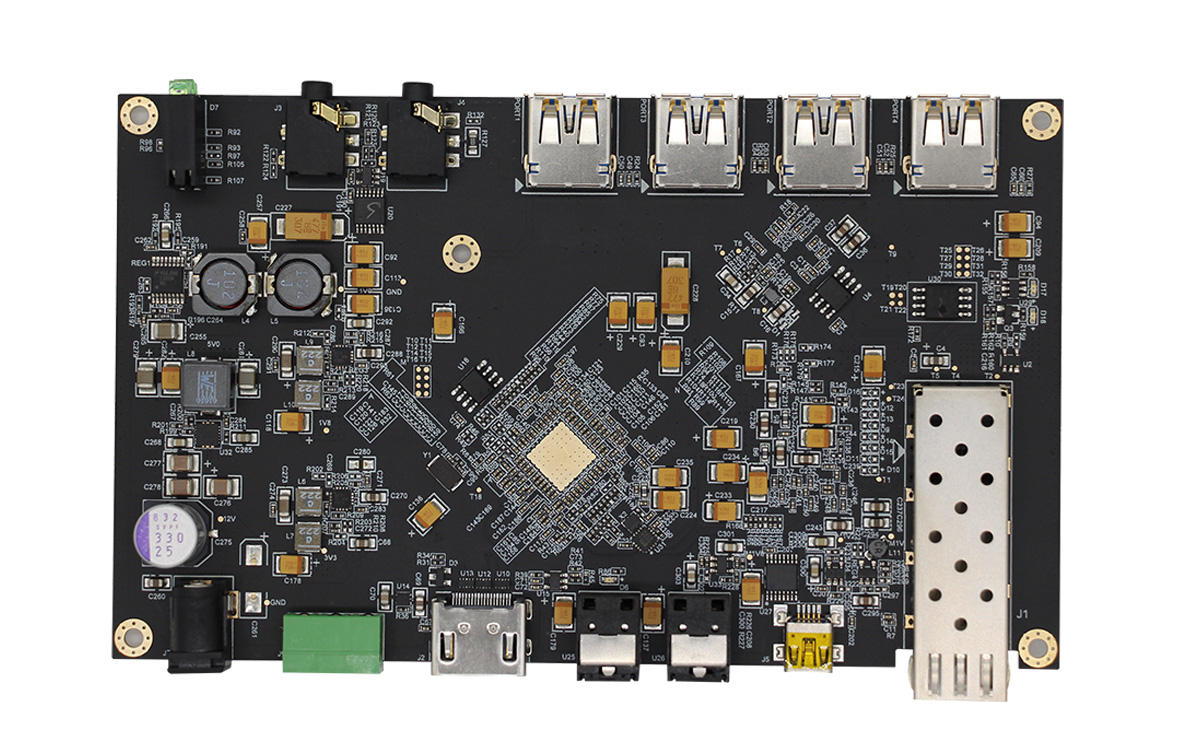

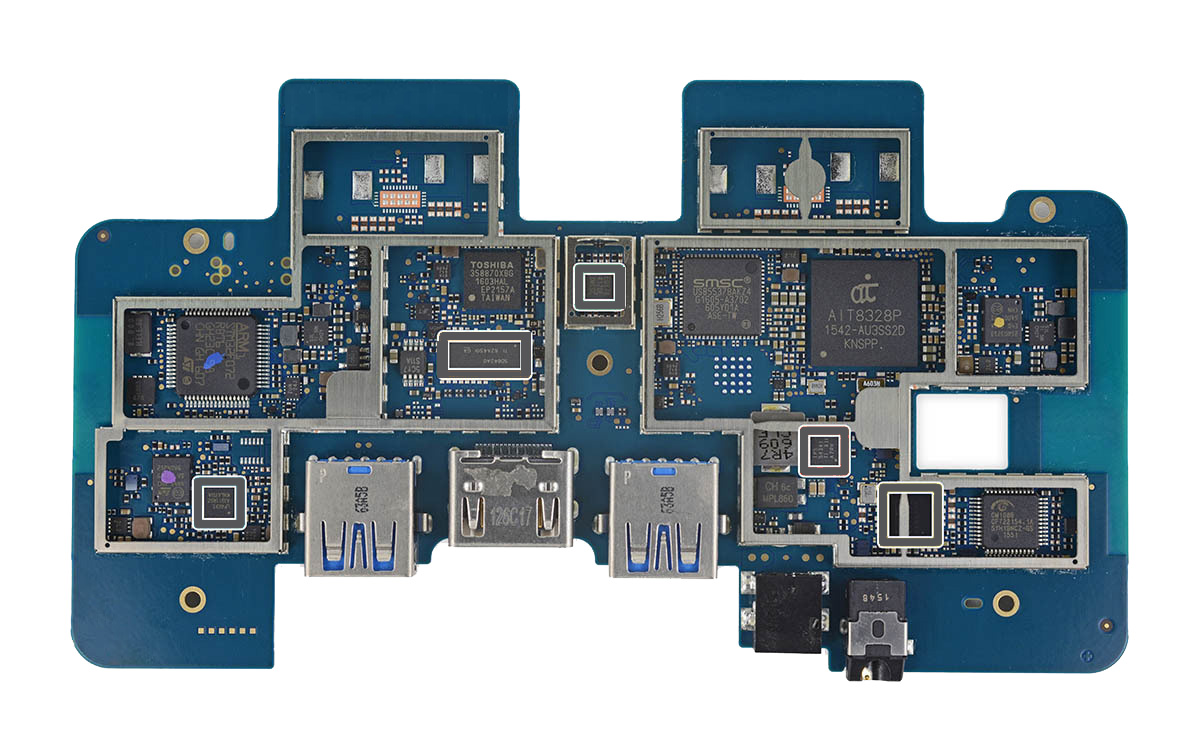

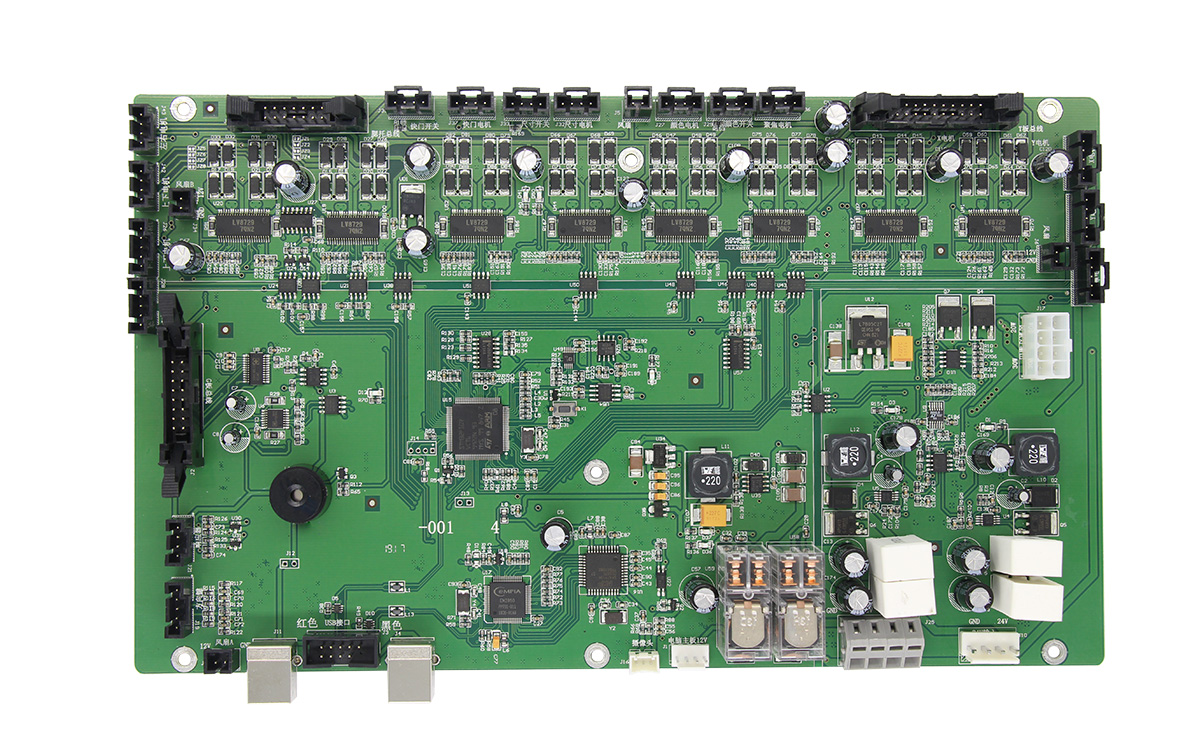

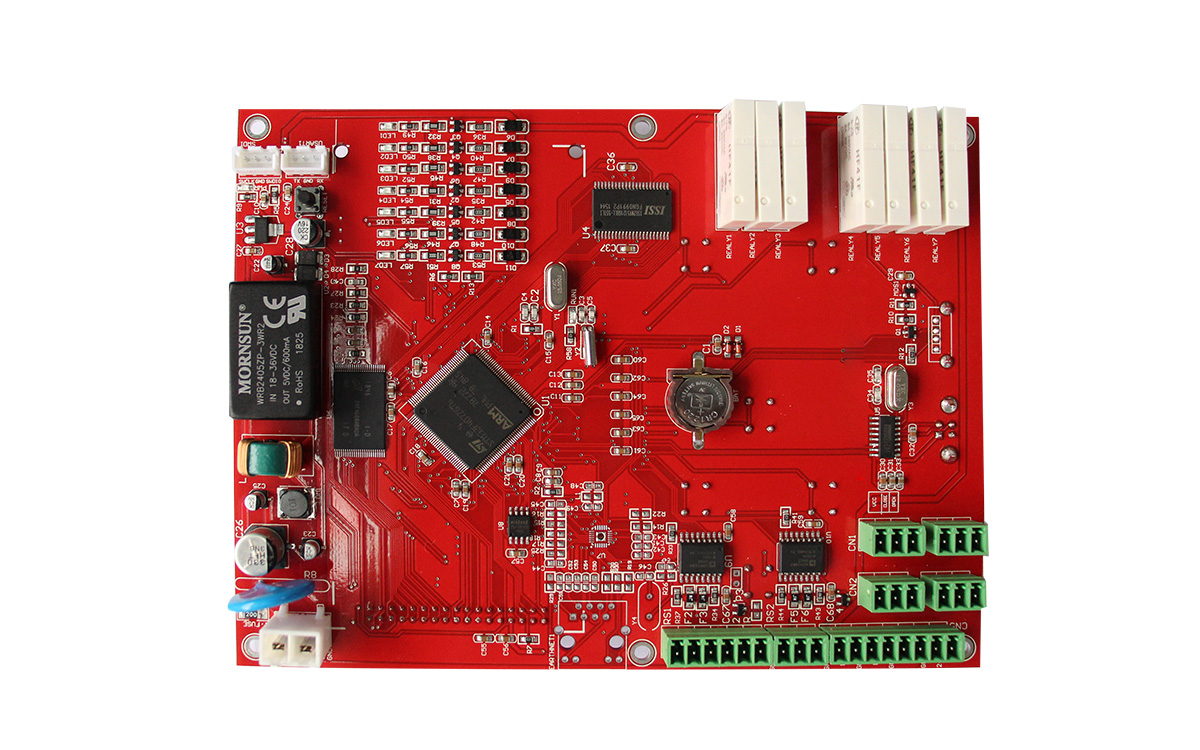

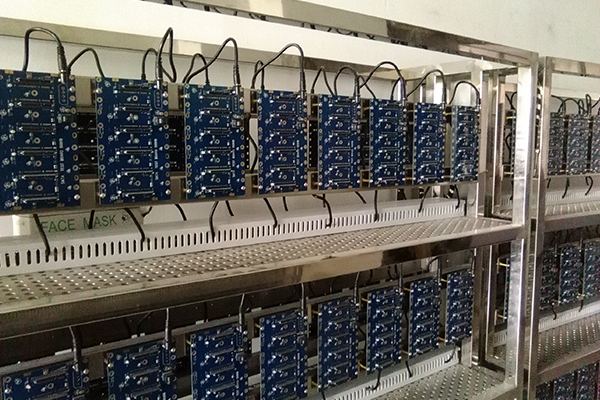

PCBA Partial Case Nuni

Masana'antar Aerospace

Masana'antu Kula da Masana'antu

Kayan Wutar Lantarki na Masu Amfani

Kayan Wutar Lantarki na Masu Amfani

Masana'antar Likita

Masana'antar Motoci

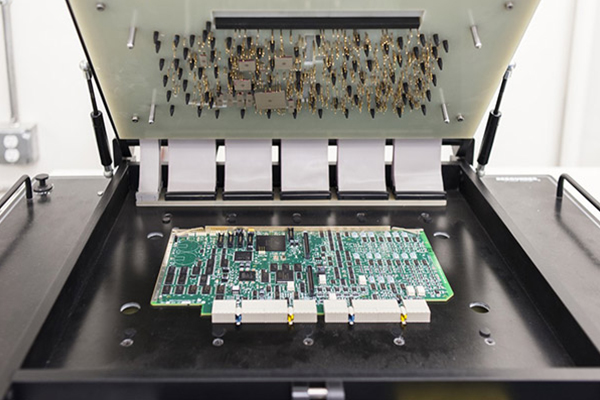

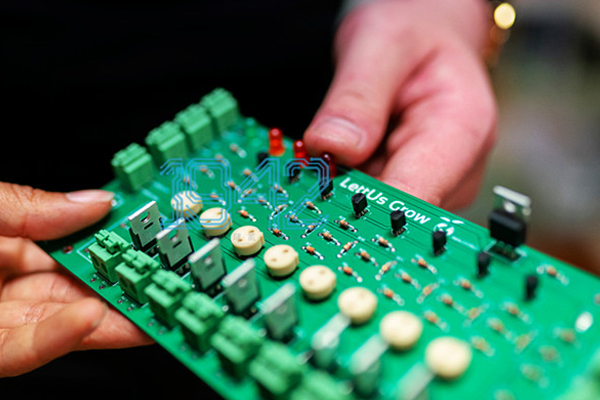

Wurin gwajin PCB wuri ne na musamman da aka tanada akan allon da'ira da aka buga (PCB) don auna wutar lantarki, watsa sigina da gano kuskure.

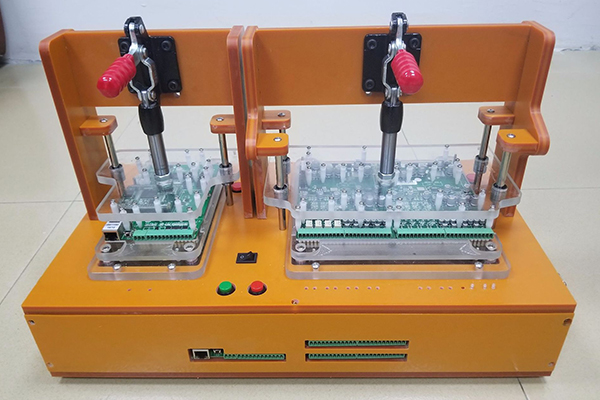

Abokan ciniki kuma za su iya tsara hanyoyin gwaji bisa ga wuraren gwaji, kuma za mu yi na'urorin gwaji don gwaje-gwajen kwaikwaiyo na ƙwararru.

☑ Ayyukan su sun haɗa da: ma'aunin lantarki Ana iya amfani da wurin gwajin don auna ƙarfin lantarki, halin yanzu, impedance da sauran sigogin lantarki na kewaye don tabbatar da aiki na yau da kullun da aikin da'ira.

☑ watsa sigina:Ana iya amfani da wurin gwajin azaman fil ɗin sigina don haɗawa da wasu na'urorin lantarki ko kayan gwaji don cimma shigar da sigina da fitarwa.

☑ Tabbatar da ƙira:

Ta wurin gwajin gwajin, tabbatar da daidaito da aiki na ƙirar PCB don tabbatar da cewa allon kewayawa yana aiki daidai da buƙatun ƙira.

☑ Ganewar kuskure:

Lokacin da kuskuren da'ira ya faru, zaku iya gano kuskuren bisa ga wurin gwaji don taimakawa injiniyoyi su nemo sanadin da kuma maganin matsalar.

☑ Gyaran gaggawa:

Lokacin da ake buƙatar maye gurbin ko gyara abubuwan da'ira, ana iya amfani da wuraren gwaji don haɗawa da sauri da cire haɗin da'irori, sauƙaƙe aikin gyarawa.