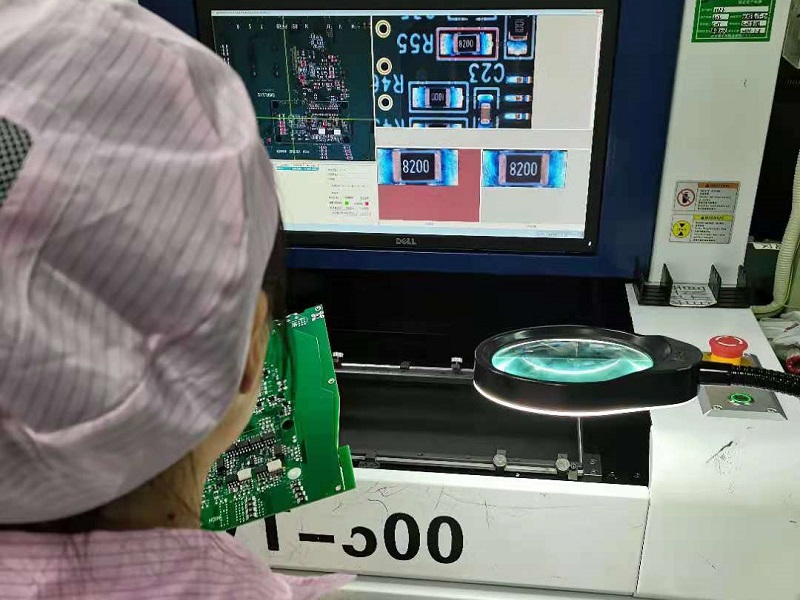

ʻO ka PCBA AOI (Printed Circuit Board Assembly Automated Optical Inspection) ka mea nui o ka nānā ʻana i kēia mau ʻano:

1. Ke kūlana hui a me ka polarity: E nānā inā ua hoʻokomo pono ʻia ke kūlana a me ka polarity ma kaPCB.

2. Nalo aoffset nā ʻāpana: E ʻike inā he nalo a i ʻole nā ʻāpana offset.

3. Ka maikaʻi o ka welding: E nānā i ka maikaʻi o ka welding, e like me ka pau ʻana o ka hoʻopili ʻana, inā ʻaʻahu like nā hui solder, inā he wili pōkole a i ʻole nā kaapuni hāmama, etc.

4. Ka maikaʻi o ka welding pad: E nānā i ka maikaʻi o ka pad welding, me ka hoʻopiha ʻana o ka pad welding, inā he oxidation, inā he pōkole pōkole a i ʻole kahi kaapuni hāmama, etc.

5. Welding deviation: E nānā inā e hoʻokaʻawale ke kūlana kuʻi mai nā koi hoʻolālā.

Ma o ka ʻike ʻana i ka ʻike ma luna, hiki i ka PCBA AOI ke kōkua i ka hōʻoia i ka maikaʻi a me ka hilinaʻi oHui PCBa hoʻomaikaʻi i ka hana hana a me ka maikaʻi o ka huahana.

Ka manawa hoʻouna: Mar-26-2024