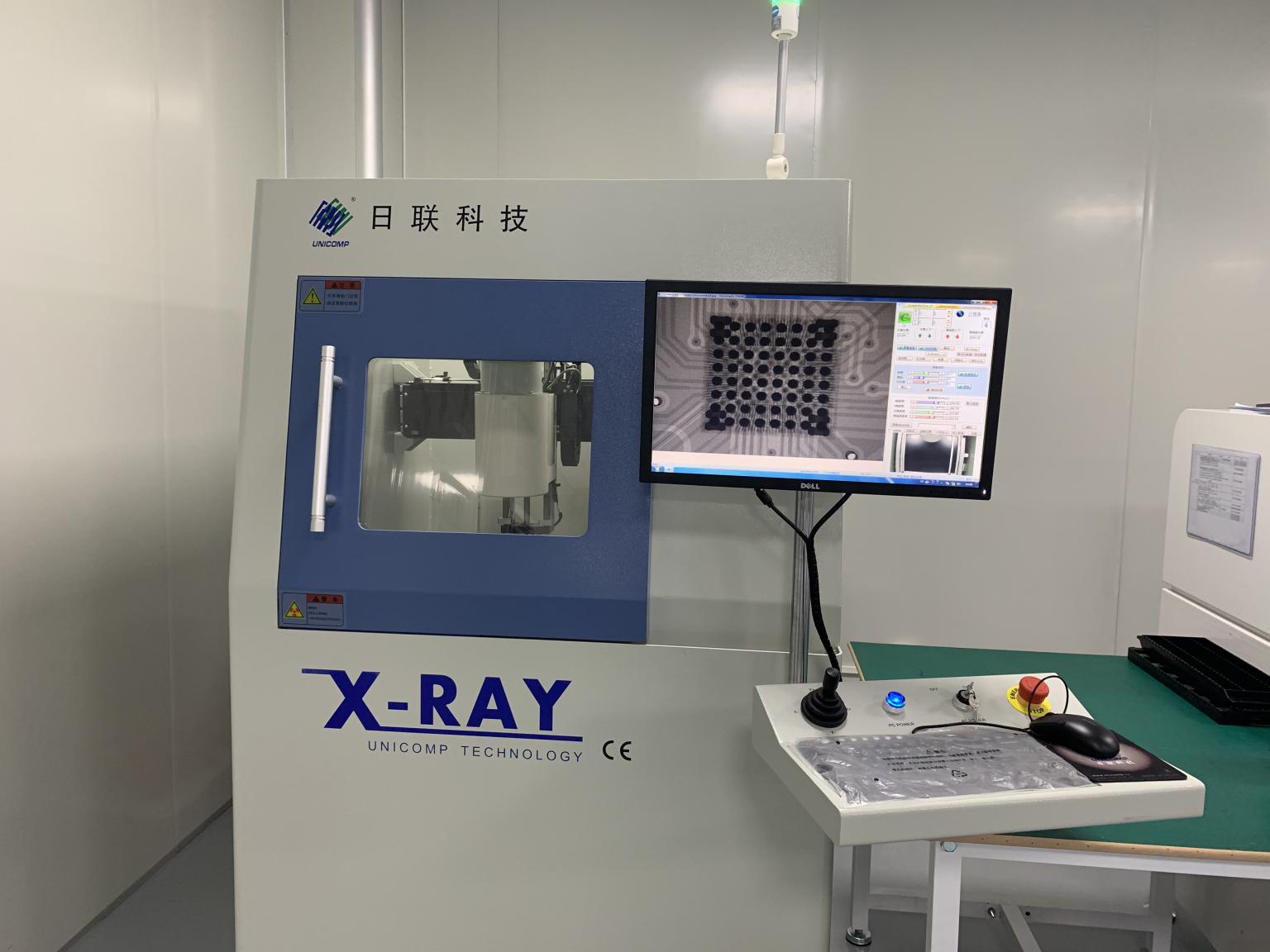

Nānā X-Ray i ka maikaʻi o ka PCBA

He ala kūpono ka nānā ʻana i ka X-ray no ka nānā ʻana i ka maikaʻi o kahi hui papa kaapuni paʻi (PCBA).Hāʻawi ia i ka hoʻāʻo ʻole luku a hāʻawi i kahi kikoʻī a me ka ʻike piha o ka PCB o loko.

Eia kekahi mau mea nui e noʻonoʻo ai i ka wā e hoʻohana ai i ka nānā X-ray no ka nānā ʻanaPCBA maikaʻi:

● Hoʻokomo i nā mea: X-ray inspection hiki ke hōʻoia i ka pololei a me ka alignment o nā mea ma ka PCB.Hoʻopaʻa ia i nā ʻāpana āpau i nā wahi kūpono a pololei hoʻi.

● Hoʻohui Solder: Hiki i ka nānā ʻana i ka X-ray ke ʻike i nā hemahema a i ʻole nā anomalies i loko o nā hui solder, e like me ka lawa ʻole a i ʻole ka nui o ka solder, solder bridging, a i ʻole ka pulu ʻana.Hāʻawi ia i kahi nānā kikoʻī i ka maikaʻi o nā pilina solder.

● Nā Kaapuni pōkole a me ka wehe ʻana: Hiki i ka nānā ʻana i ka X-ray ke ʻike i nā kaapuni pōkole a i ʻole ka wehe ʻana i loko o ka PCB, ma muli o ke kuhi hewa ʻana a i ʻole ke kūʻai pono ʻole ʻana o nā ʻāpana.

● Delamination a me nā māwae: X-hihi hiki ke hōʻike i kekahi delamination a māwae paha i loko o kaNā papa o loko o ka PCBaiʻole ma waena o nā papa, e hōʻoiaʻiʻo ana i ka paʻa o ka papa.

● Nānā BGA: He mea pono loa ka nānā ʻana i nā kukui X no ka nānā ʻana i nā ʻāpana pōlele kiʻi (BGA).Hiki iā ia ke hōʻoia i ka maikaʻi o nā pōpō solder ma lalo o ka pūʻolo BGA, e hōʻoia ana i nā pili pono.

● Hōʻoia DFM: Hiki ke hoʻohana ʻia ka nānā ʻana i ka X-ray e hōʻoia i ka hoʻolālā no ka hana ʻana (DFM) nā ʻano o ka PCB.Kōkua ia i ka ʻike ʻana i nā hemahema hoʻolālā a me nā pilikia hana hana.

ʻO ka holoʻokoʻa, ʻo ka nānā ʻana i ka X-ray he mea hana waiwai no ka loiloi i ka maikaʻi o kahi PCBA.Hāʻawi ia i kahi hiʻohiʻona kikoʻī o ka hale i loko, e ʻae ai i ka nānā pono ʻana a me ka hōʻoia ʻana e hoʻokō ka papa i nā kūlana maikaʻi i koi ʻia.

Ka manawa hoʻouna: Oct-11-2023