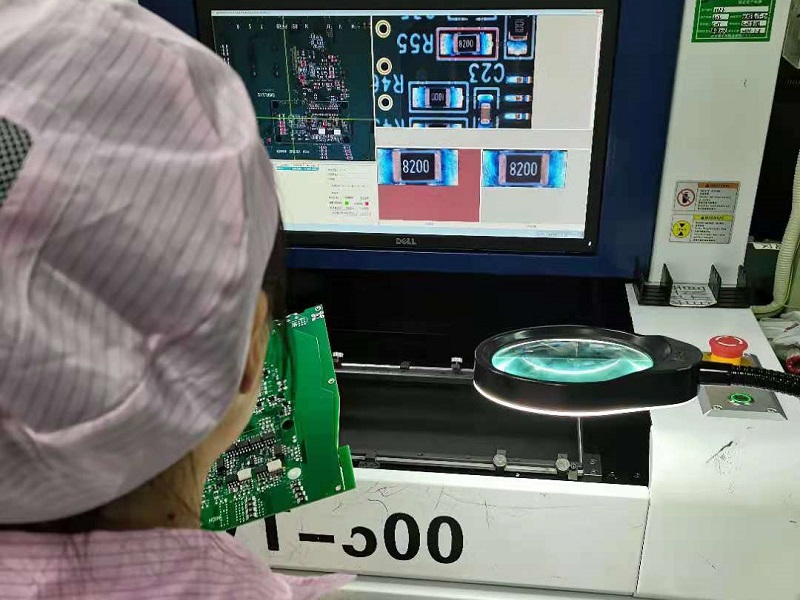

PCBA AOI (Bipụta Circuit Board Assembly Automated Optical Inspection) ọdịnaya nyocha gụnyere akụkụ ndị a:

1. Component ọnọdụ na polarity: Lelee ma akụrụngwa ọnọdụ na polarity na-n'ụzọ ziri ezi arụnyere naPCB.

2. Na-efu efu nadechapụ components: Chọpụta ma ihe ndị na-efu efu ma ọ bụ mebie.

3. Ịgbado ọkụ àgwà: Lelee àgwà ịgbado ọkụ, gụnyere ma ịgbado ọkụ zuru ezu, ma solder nkwonkwo bụ edo, ma e nwere welding obere sekit ma ọ bụ na-emeghe sekit, wdg.

4. Ịgbado ọkụ àgwà: Lelee àgwà nke welding pad, gụnyere ma welding pad zuru ezu, ma ọ bụ oxidation, ma e nwere obere sekit ma ọ bụ oghere oghere, wdg.

5. Welding deviation: Lelee ma ịgbado ọkụ ọnọdụ deviates si imewe chọrọ.

Site na nchọpụta nke ọdịnaya dị n'elu, PCBA AOI nwere ike inyere aka hụ na ịdị mma na ntụkwasị obi nkePCB mgbakọma melite nrụpụta mmepụta na ịdị mma ngwaahịa.

Oge nzipu: Mar-26-2024