To avoid wave soldering PCBA quality problems, you can take the following measures:

Reasonable selection of solder: Make sure to choose solder materials that meet quality standards to ensure welding quality.

Control wave soldering temperature and speed: Strictly control wave soldering temperature and speed to avoid PCBA quality problems caused by overheating or too fast welding.

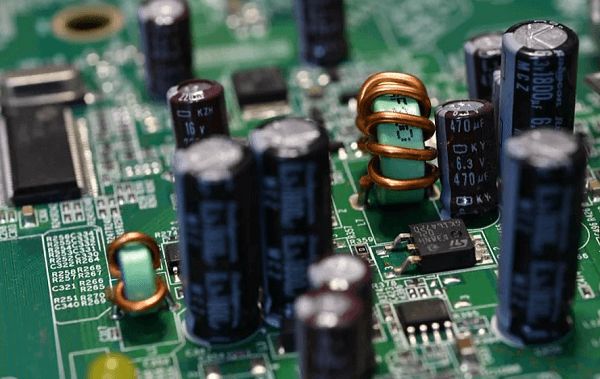

Use high-quality PCB boards and components: Choose high-quality PCB boards and components to ensure soldering reliability and stability.

Regular maintenance of equipment: Ensure that wave soldering equipment is in good working condition and perform regular maintenance and upkeep to ensure welding quality.

Conduct welding quality inspection: After the wave soldering is completed, welding quality inspection and testing are performed to ensure the integrity and reliability of the solder joints. Through the above measures, PCBA quality problems in wave soldering can be effectively avoided and the quality and efficiency of PCBA production can be improved.

Post time: Jan-25-2024