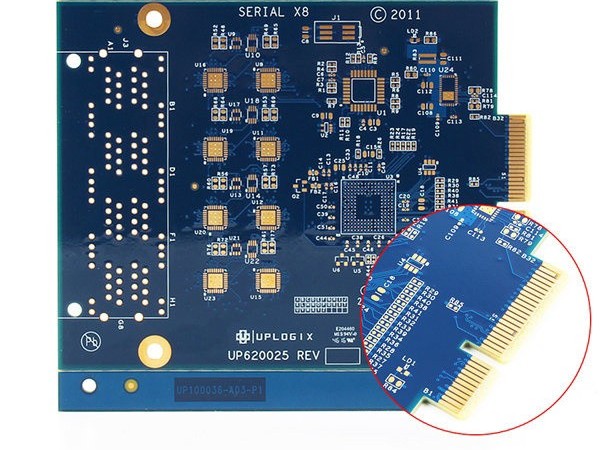

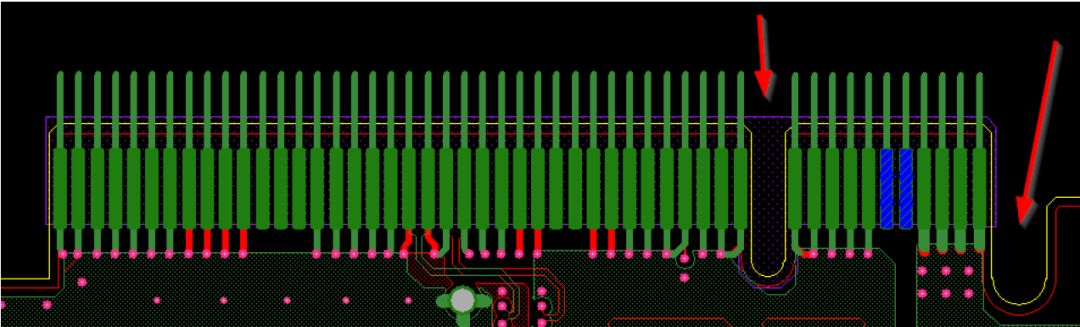

PCB gold fingers refer to the edge metallization treatment part on the PCB board.

In order to improve the electrical performance and corrosion resistance of the connector, the gold fingers usually use gold plating process. The following is a typical PCB gold finger gold plating production process:

Cleaning: First, the edges of the PCB board need to be cleaned and deburred to ensure the smoothness and cleanliness of the surface.

Surface treatment: Next, the edge of the PCB needs to be surface treated, usually through chemical copper plating, pickling and other processes to remove dirt and oxide layers in preparation for subsequent gold plating.

Gold plating: After surface treatment, the gold finger will go through an electroplating process. By coating a metal solution on the edge of the PCB board and applying current, the metal is deposited on the surface to form a uniform metal protective layer.

Cleaning and testing: After gold plating is completed, the gold fingers need to be cleaned to remove residual chemicals and impurities. Quality inspection is then carried out to ensure that the quality and thickness of the metallization layer of the gold finger meets the requirements. These process steps ensure the gold plating quality and good electrical performance of PCB gold fingers, while also improving its corrosion resistance and connection stability.

Post time: Mar-07-2024