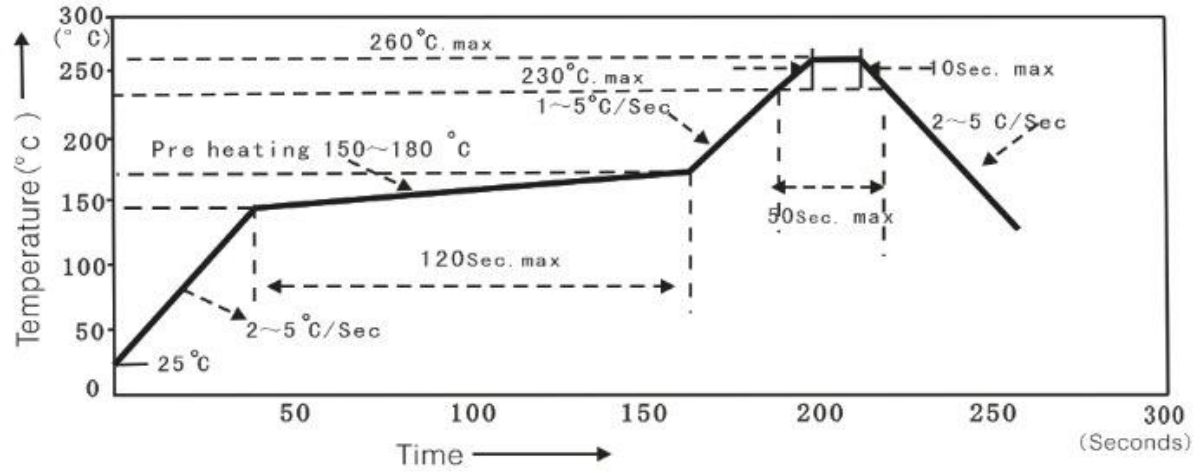

PCBA SMT temperature zone control refers to the temperature control during the printed circuit board assembly (PCBA) process in surface mount technology (SMT).

During the SMT process, temperature control is critical to welding quality and assembly success. Temperature zone control usually includes the following aspects:

Preheat zone: used to preheat PCB and components to reduce thermal shock and ensure uniformity of welding.

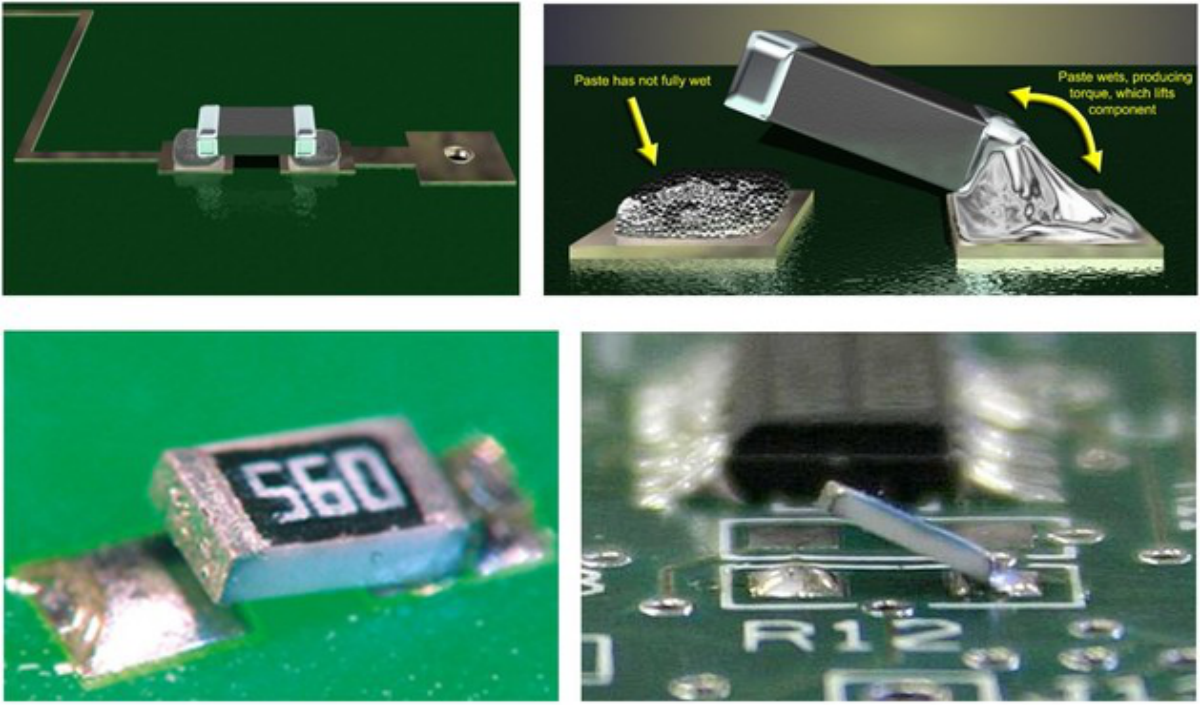

Welding zone: maintain the appropriate temperature to allow the welding material to reach the melting point and achieve welding.

Cooling zone: After the welding is completed, the temperature is controlled to ensure the quality of the welding and prevent component displacement or stress problems caused by excessive cooling.

Through precise temperature zone control, the quality and stability of PCBA can be ensured, production efficiency can be improved and defect rates can be reduced. Commonly used equipment includes reflow ovens and hot blast furnaces.

Post time: Jan-05-2024