The main purpose of PCBA waterproof COATING is to protect circuit boards and other electronic components in electronic products from moisture, humidity or other liquids.

Here are a few main reasons why PCBA waterproof COATING is necessary:

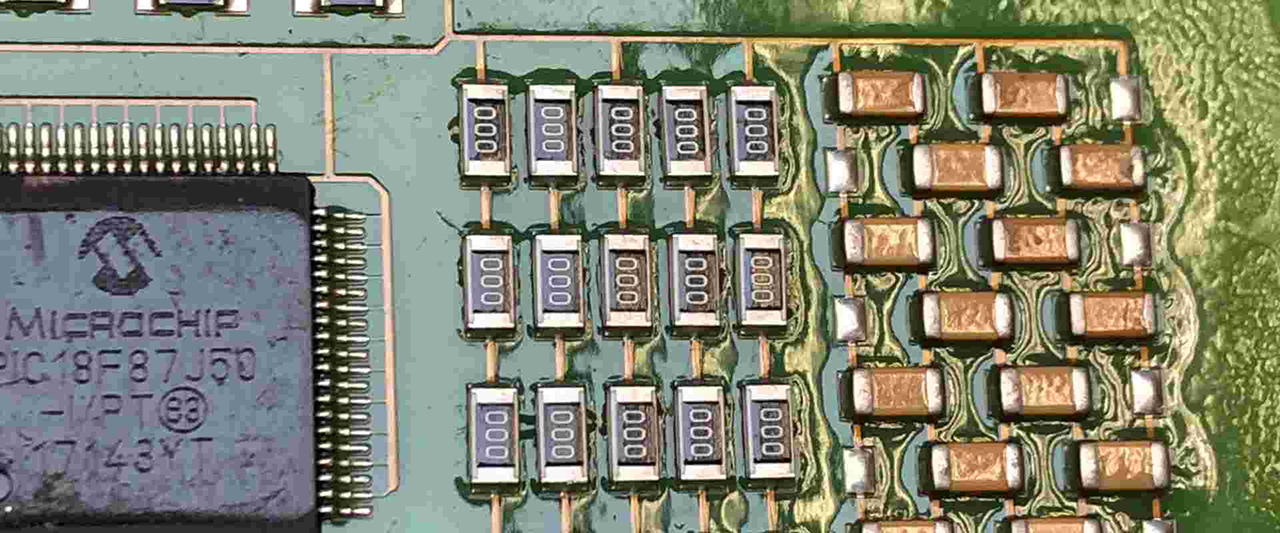

Prevent circuit boards from getting damp: Circuit boards are the core component of electronic products, and the electronic components in them are very sensitive to moisture. If the circuit board gets wet, it may cause short circuit, oxidation, corrosion and other problems, or even damage the entire circuit. PCBA waterproof COATING can effectively isolate the contact between the circuit board and the humid environment, reducing the risk of the circuit board getting damp.

Prevent circuit board corrosion: Humidity and other liquids can cause corrosion on the surface of electronic components, causing circuit board damage or improper operation. PCBA waterproof COATING can form a protective layer to prevent moisture and liquid from invading electronic components and reduce the possibility of corrosion.

Improve product reliability: PCBA waterproof COATING can improve the reliability and life of electronic products. Waterproof coating can not only reduce the failure rate of circuit boards, but also prevent damage to electronic components from moisture and humid environments, thereby extending the service life of the entire product.

Suitable for harsh environment application scenarios: Many electronic products need to work in harsh environmental conditions, such as outdoor equipment, automotive electronic systems, etc. In these scenarios, PCBA waterproof COATING can provide additional protection, allowing electronic products to work normally in harsh environments such as moisture, dust, and high temperatures.

All in all, PCBA waterproof COATING can increase the durability, reliability and adaptability of electronic products, reduce problems caused by moisture and humidity, and improve overall performance and user experience.

Post time: Nov-29-2023