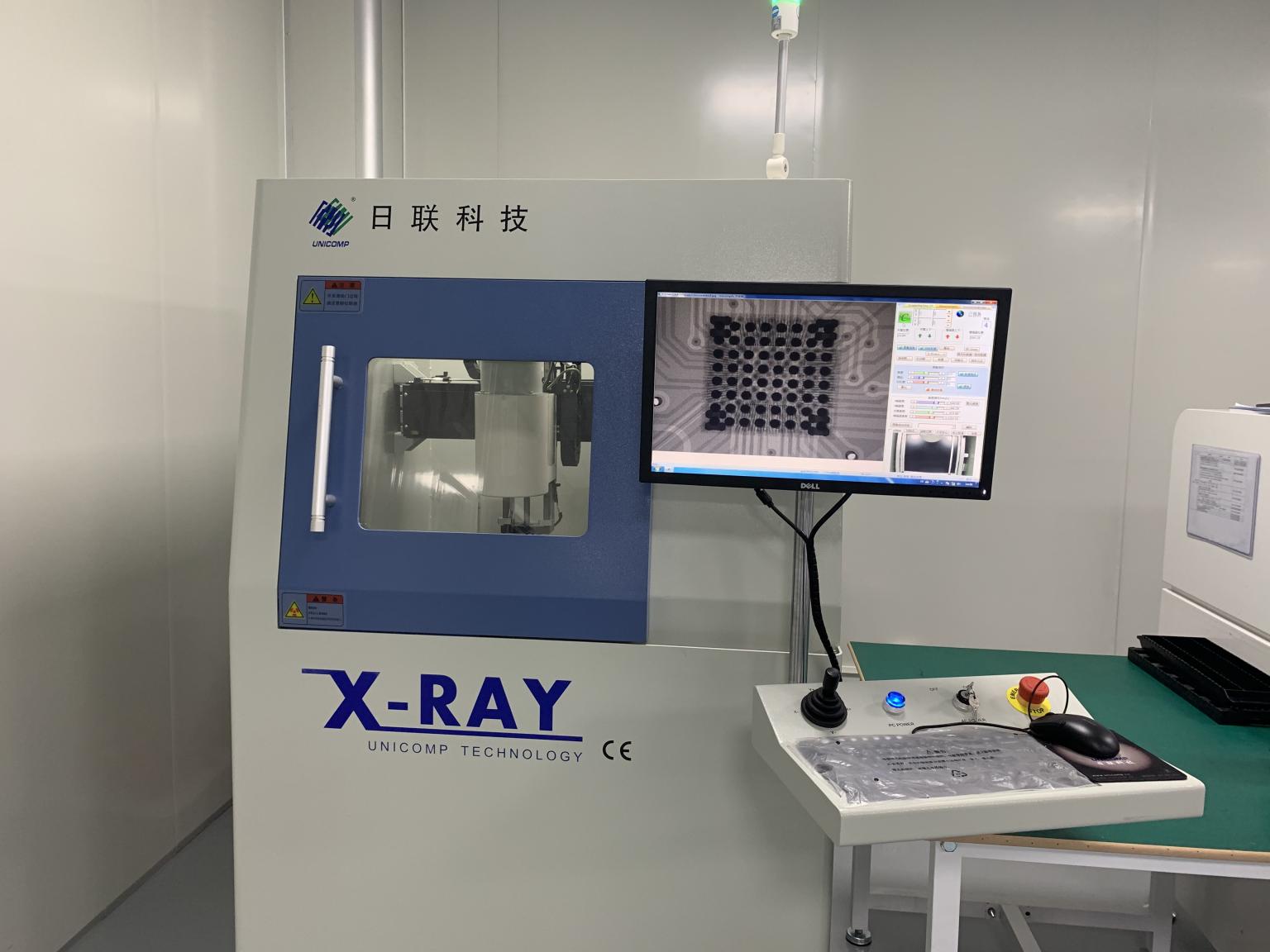

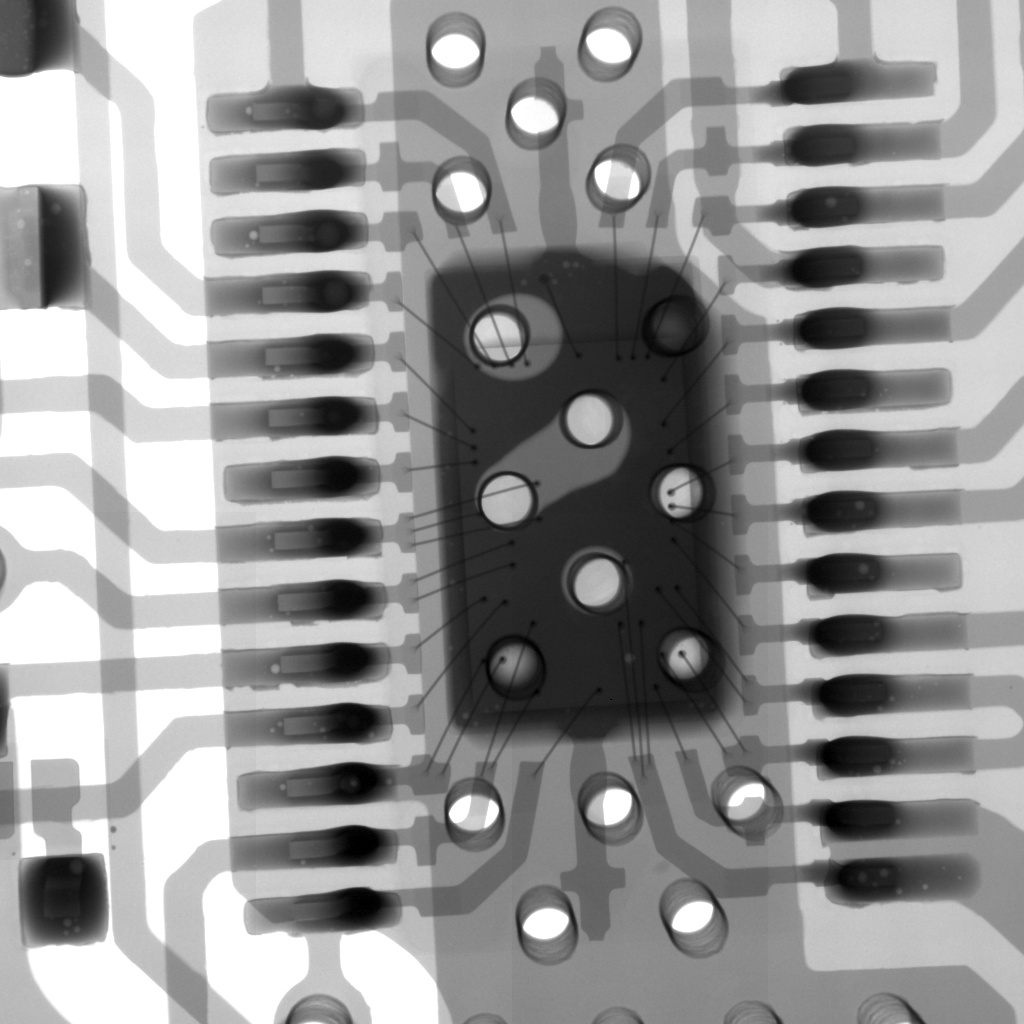

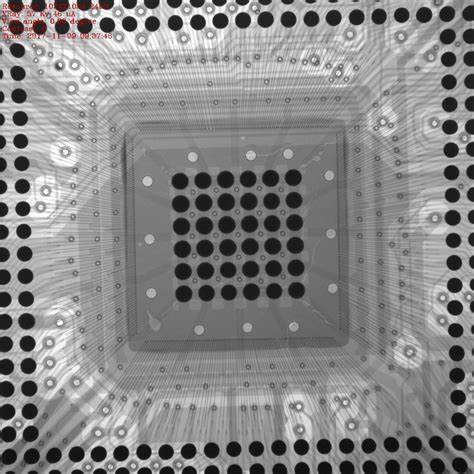

X-Ray Inspection of PCBA (Printed Circuit Board Assembly) is a non-destructive testing method used to check the welding quality and internal structure of electronic components. X-rays are high-energy electromagnetic radiation that is penetrating and can pass through objects, such as PCBAs, to reveal their internal structures. X-ray inspection equipment usually consists of the following main parts: 1. X-ray generator: generates high-energy X-ray beams. 2. X-ray detector: Receives and measures the intensity and energy of the X-ray beam passing through the PCBA. 3. Control system: controls the operation of the X-ray generator and detector, and processes and displays the detection results. The working principle of X-ray detection is as follows: 1. Preparation: Place the PCBA to be inspected on the workbench of the X-ray inspection equipment, and adjust the parameters of the equipment, such as the energy and intensity of X-rays, as needed. 2. Emit X-rays: The X-ray generator generates a high-energy X-ray beam, which passes through the PCBA. 3. Receive X-rays: The X-ray detector receives the X-ray beam passing through the PCBA and measures its intensity and energy. 4. Processing and display: The control system processes and analyzes the received X-ray data, generates images or videos, and displays them on the monitor. These images or videos can show information such as the soldering quality, component location and internal structure of the PCBA. Through X-ray inspection, the integrity of welding points, welding quality, welding defects (such as cold welding, short circuit, open circuit, etc.), component position and orientation, etc. can be checked. This non-destructive inspection method can help improve the quality and reliability of PCBA and reduce defects and failures during the manufacturing process.

Post time: Mar-12-2024