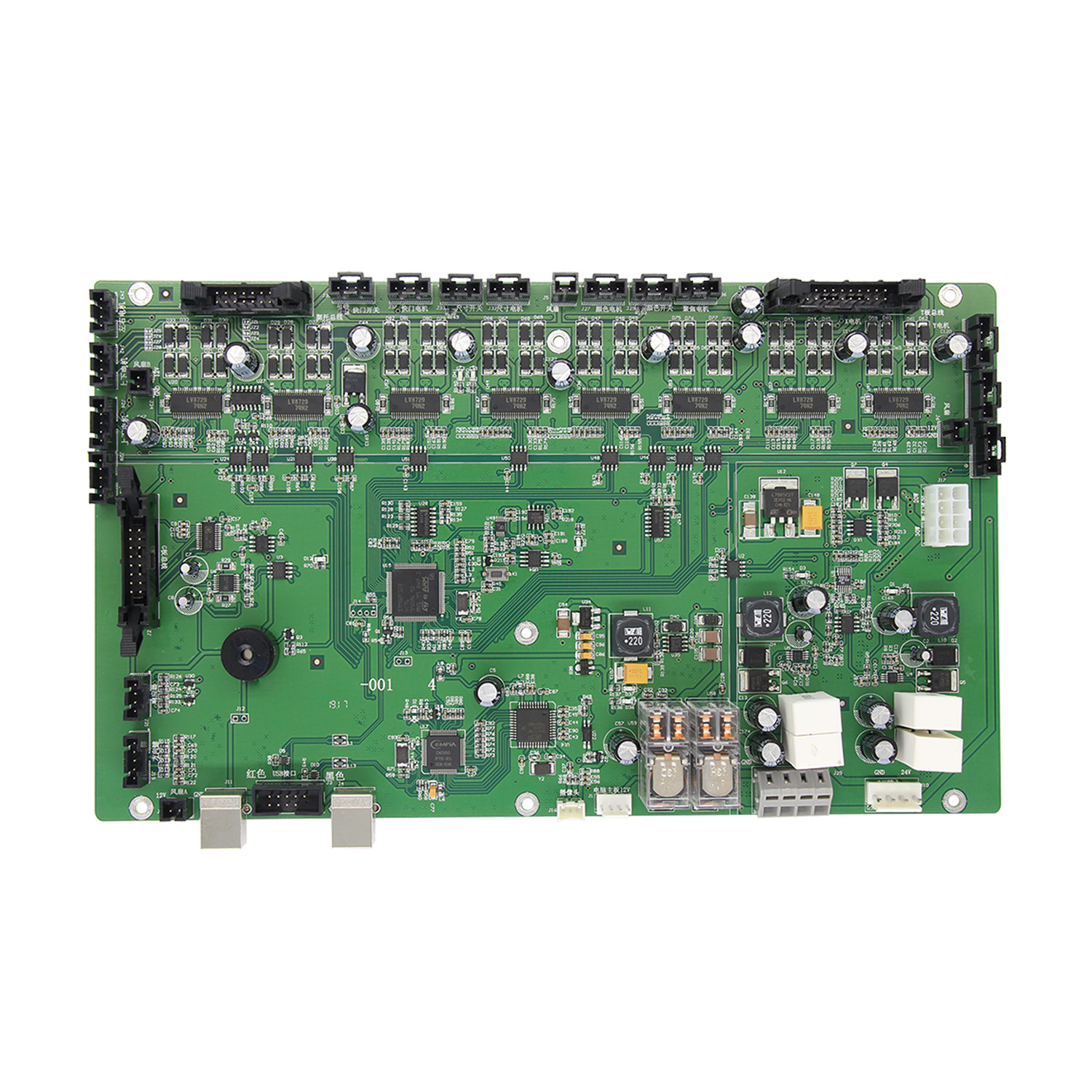

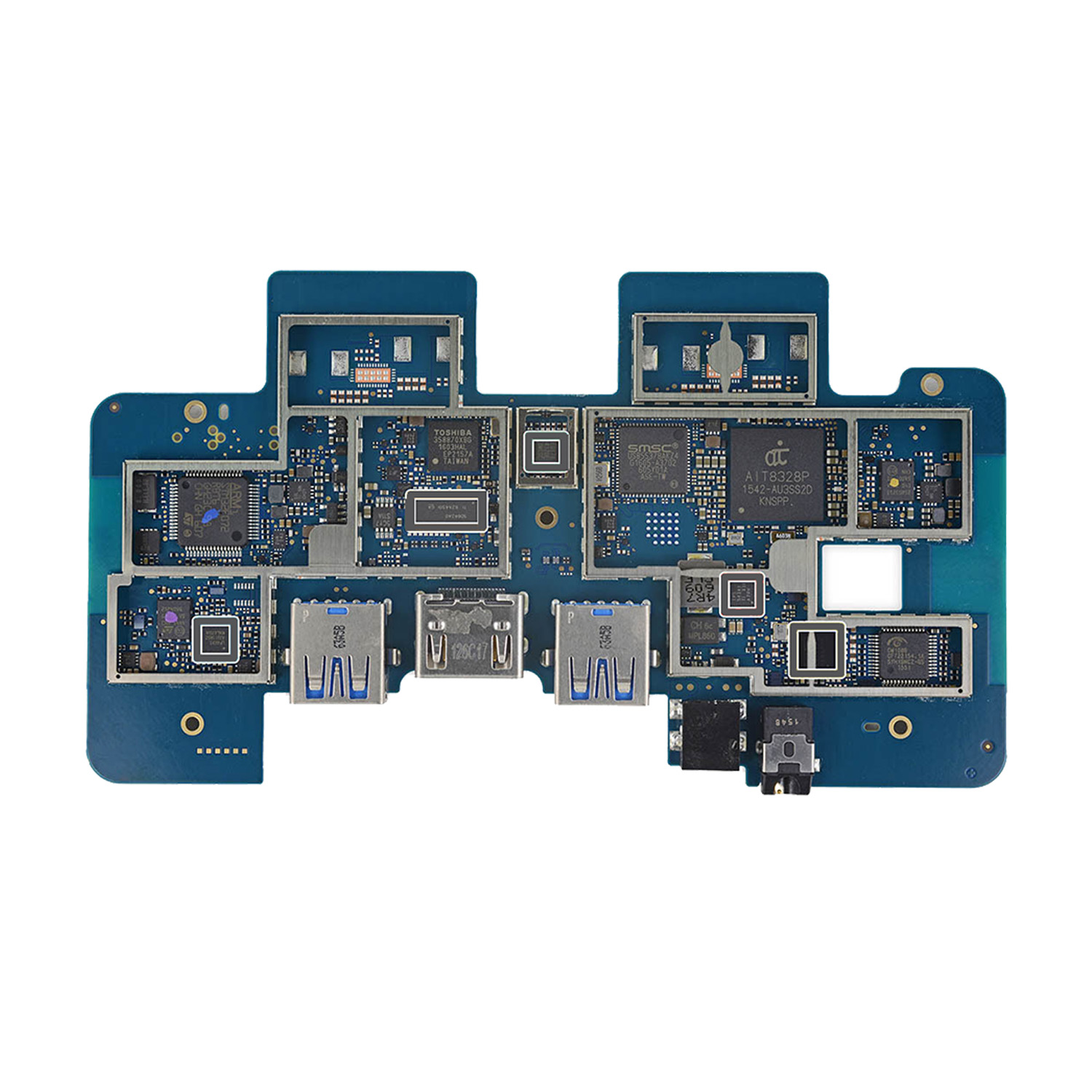

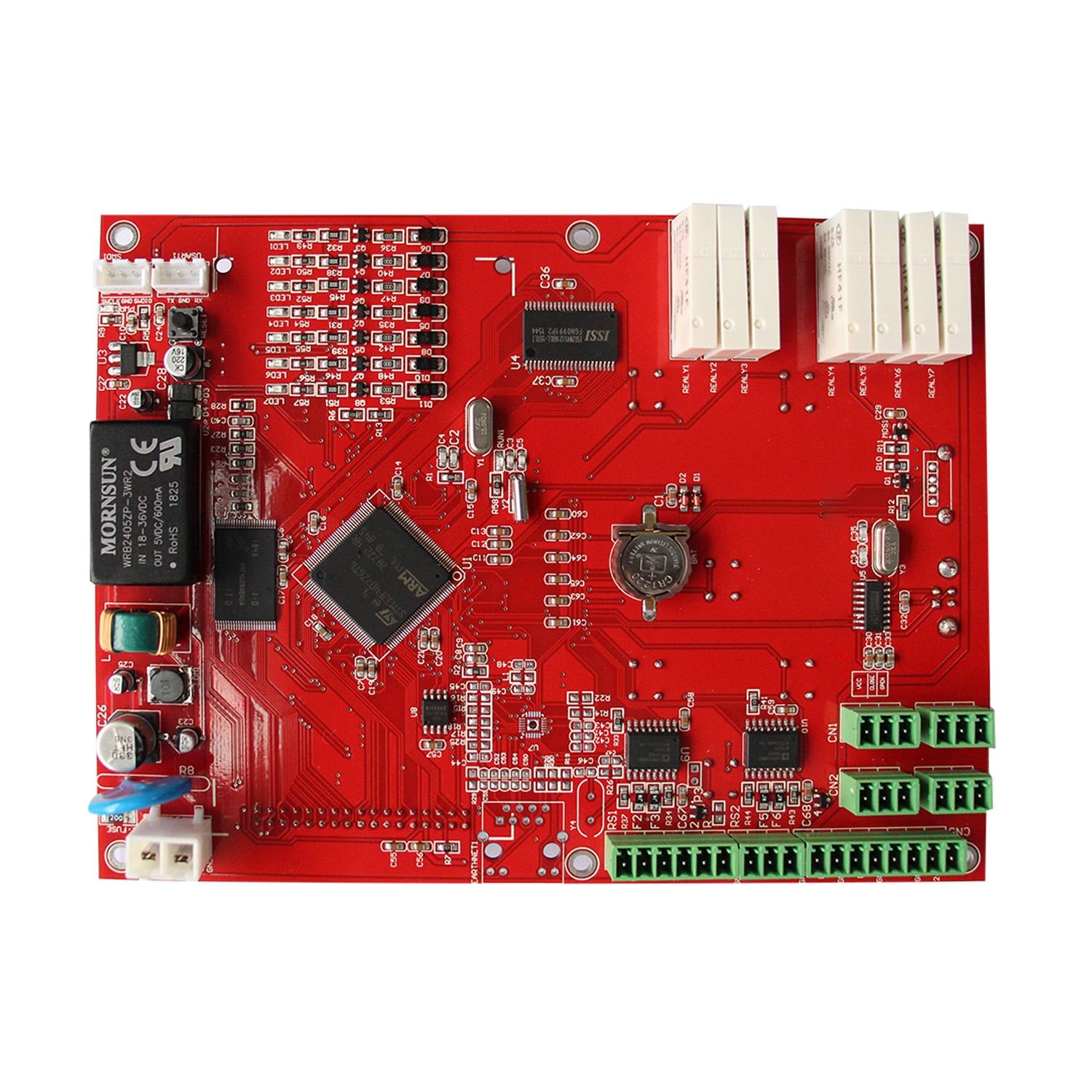

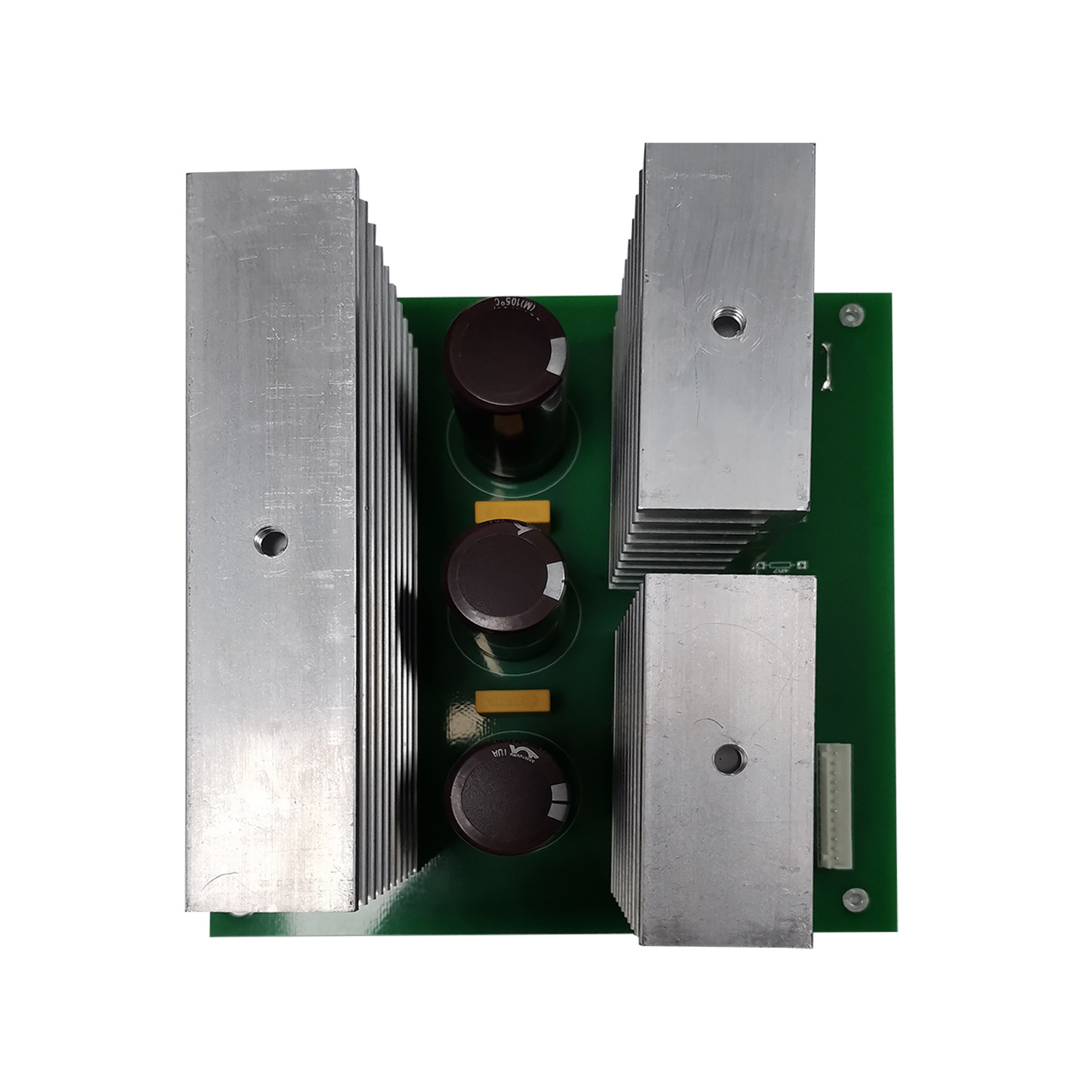

PCBA Processing Services

Fast delivery and quality assurance

Advanced equipment, escort for quality

We have advanced equipment and a professional team to provide you with high-quality line body configurations in small, medium and large quantities.

☑ In terms of delivery date, we promise that after the materials are sorted out, we will place an order online as soon as possible and deliver the goods within 24 hours to ensure that you can receive the products you need in time.

☑ The service we provide is very convenient. In addition to circuit board processing, we also provide component supply and procurement of BOM materials.

☑ We have our own PCB factory, realizing one-stop delivery. We don't need you to find multiple suppliers, we can provide you with a full set of services, simplify the procurement process, and save you time and energy.

In addition to the above services, we also provide one-to-one exclusive services such as wire mesh business, DIP plug-in, pick-up and supply.

Our team will work closely with you to develop a tailor-made solution based on your requirements and needs.

We are committed to providing you with a perfect service experience.

☑ Our equipment is very advanced, which can guarantee the quality. We have GKG automatic printing machine, SPI, Yamaha placement machine, 10-12 temperature zone air reflow soldering and nitrogen reflow soldering, AOI detector, X-ray detection automatic first article detector, selective wave soldering and BGA rework station and other advanced device of.

☑ These devices can ensure efficient, precise and stable production process, thereby improving product quality and delivery time.

Our team has rich experience and professional technical knowledge.

☑ We believe that after careful operation and strict control by our team, you will get high-quality circuit board processing services. Our services are not limited to the manufacture of products, but also include the monitoring and quality assurance of the whole process.

Whether you need small, medium or high volume circuit board processing, we can meet your needs.

Our goal is to provide you with fast, convenient and professional OEM services, and always guarantee product quality and delivery time. If you have any questions about our OEM service or need further consultation, please feel free to contact our team. We look forward to working with you and providing you with the best solution.

ONE STOP ODM/OEM MANUFACTURING SERVICE PROVIDER

ODM/OEM manufacturing services to alliance partners, including product design, product development, PCBA (printed circuit board assembly) manufacturing, and electronic product assembly services.

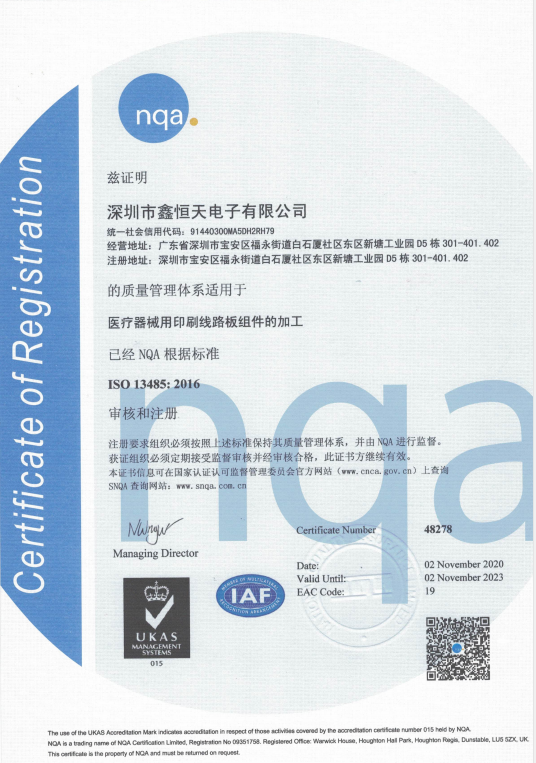

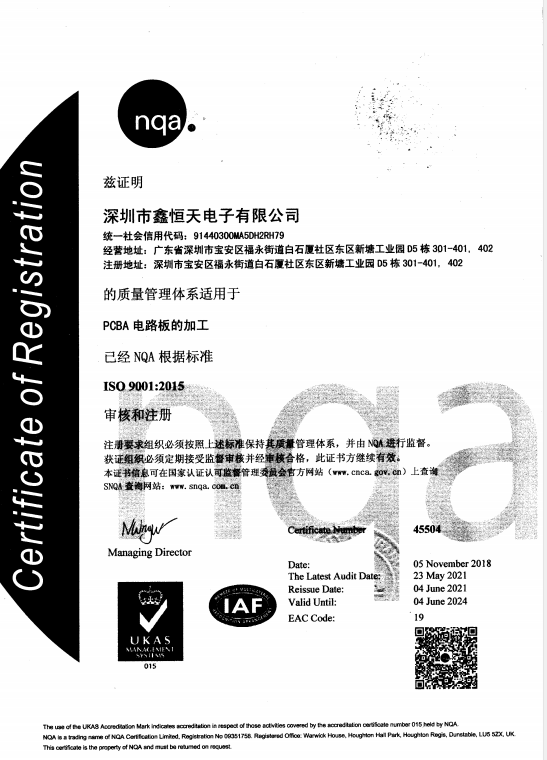

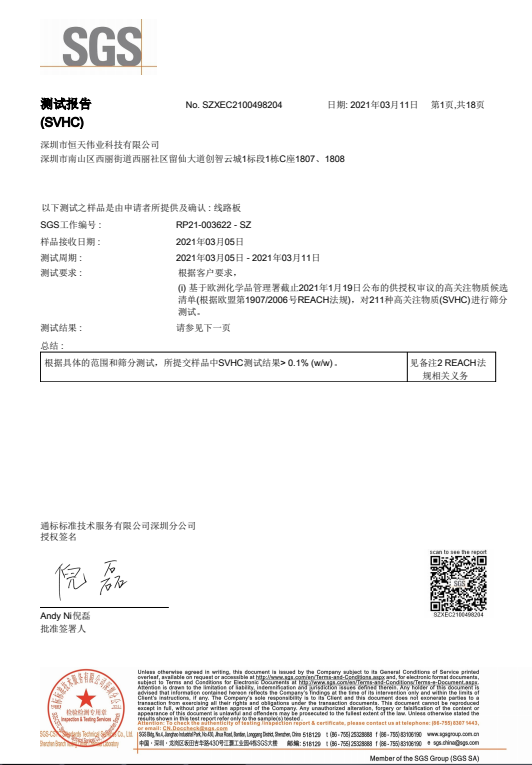

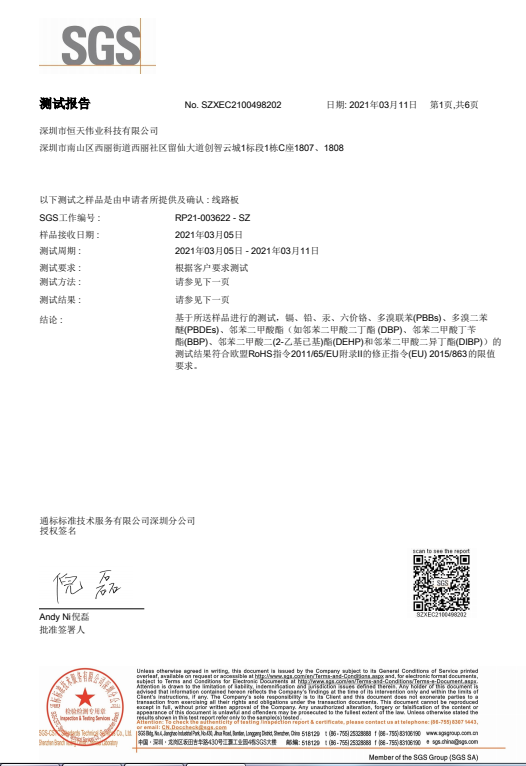

QUALITY CERTIFICATION

Has passed IATF16949, ISO13485, ISO9001, ISO14001 and other certification systems, the whole process adopts MES management system, Ensure first-class product quality and satisfy customers through automated, intelligent and systematic production management mechanisms!