Isu tinopa nyanzvi PCBA welding masevhisi kuti tive nechokwadi chekuti zvigadzirwa zvemagetsi zviri padanho repamusoro maererano nemhando uye kuita.

Sei uchisarudza yedu PCBA Welding sevhisi?

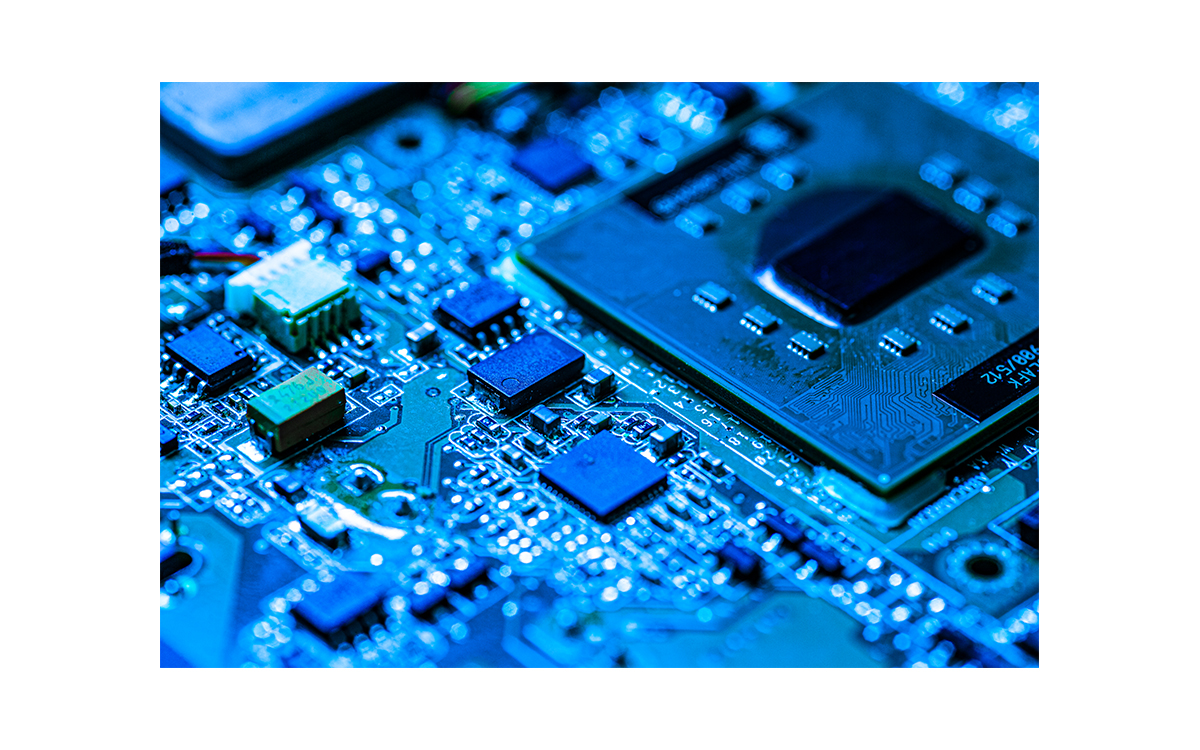

●Welding tekinoroji yemhando yepamusoro: Tine timu ine ruzivo rwehunyanzvi, inyanzvi munzira dzakasiyana siyana dzewelding uye matekinoroji, anosanganisira pamusoro pekukwira kwepamusoro tekinoroji (SMT) uye plug-in tekinoroji (THT).

Ingave chikamu chidiki chekukwira pamusoro kana yakakura plug-in chikamu, tinogona kupedzisa welding process nemazvo uye nemazvo.

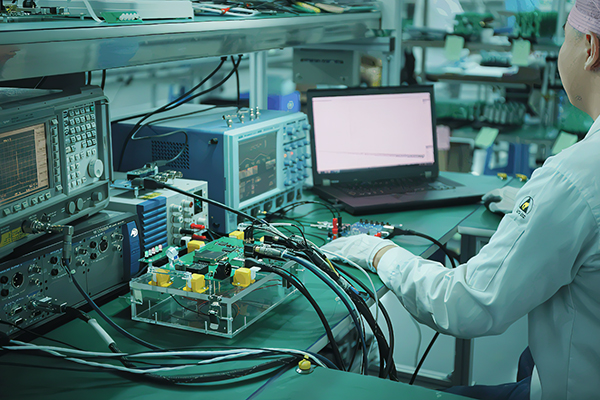

●Yakasimba yemhando yekudzora: Isu tinoisa yakasimba yemhando yekudzora maitiro kuti ive nechokwadi chekuti maitiro ese e welding anosangana nemhando yepamusoro.

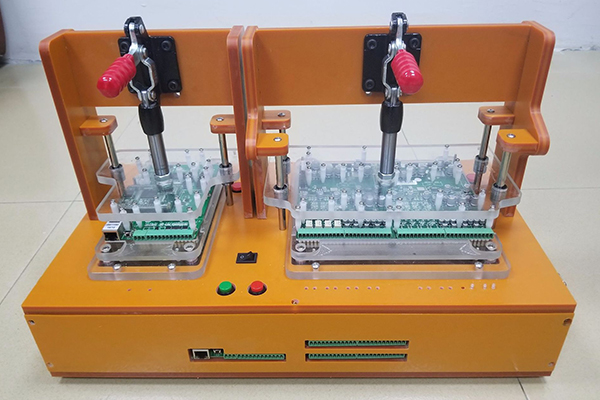

Isu tinoshandisa epamberi yekuyedza michina uye nzira dzekuitisa yakazara kuyedzwa uye kusimbiswa kweiyo solder majoini ekubatanidza, welding mhando uye kuisirwa kwakaringana kwezvikamu kuti ive nechokwadi chekuvimbika kwechigadzirwa uye kuita.

●Customized mhinduro: Tinogona kupa customized PCBA welding mhinduro maererano nezvinodiwa nevatengi.

Isu tinoshanda padhuze nevatengi vedu kuti tinzwisise zvavanoda uye zvavanotarisira, uye nekupa zano rakakodzera uye rutsigiro rwehunyanzvi kuti uwane zvakanakisa welding mhedzisiro.

Before Production

Mukugadzira

Mushure mekugadzira

Ongororo yedata

Faira optimization

BOM KupindaPurchase Application

Sample Confirmation (Project Engineer, Mutengi) Muedzo-kugadzira, Misa kugadzirwa (Injiniya yeprojekiti inotevera pane yese maitiro)

Pfupiso yeProjekiti(Rekodha faira rekudzokorora maodha) Kuteedzera kwemutengi (mushure mekutengesa sevhisi)

Imwe-Stop Pcba Processing Uye Manufacturing Service Provider

Nhoroondo ye SMT

AOI

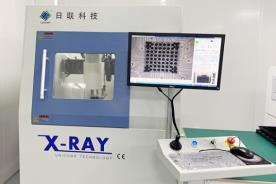

X-RAY

Lead-isina reflow soldering

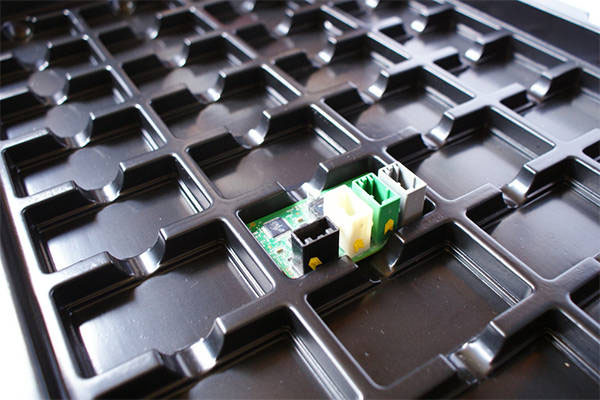

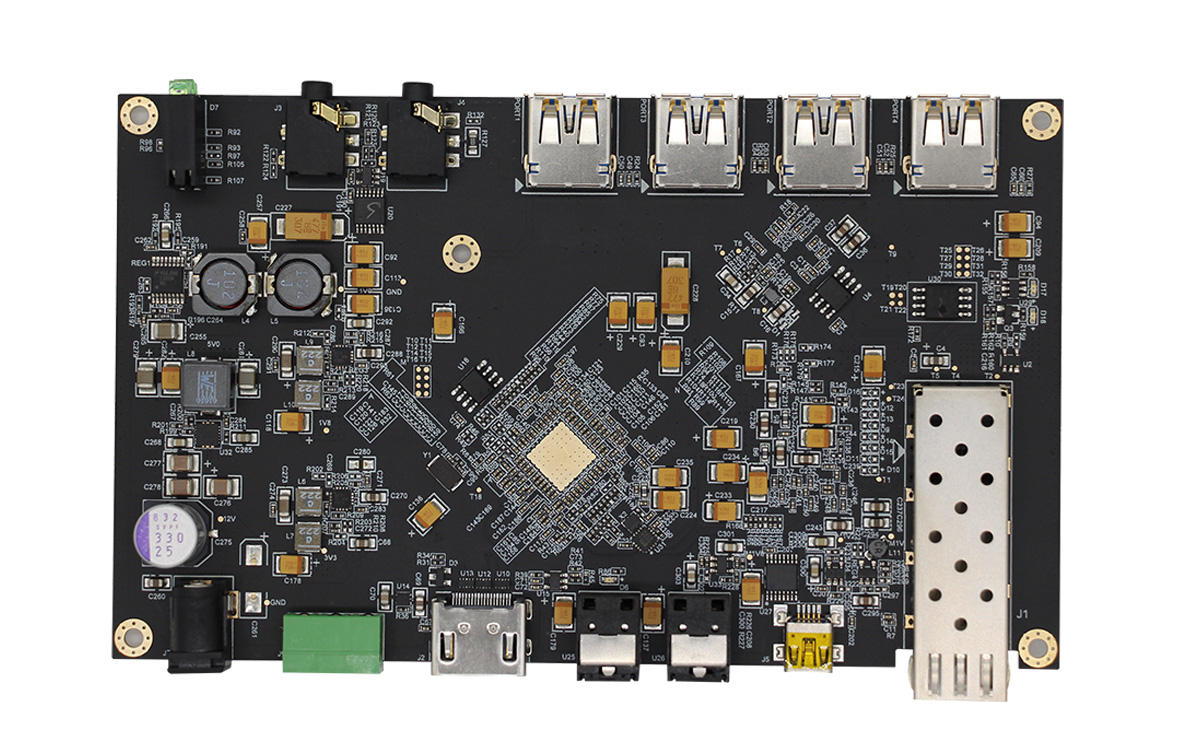

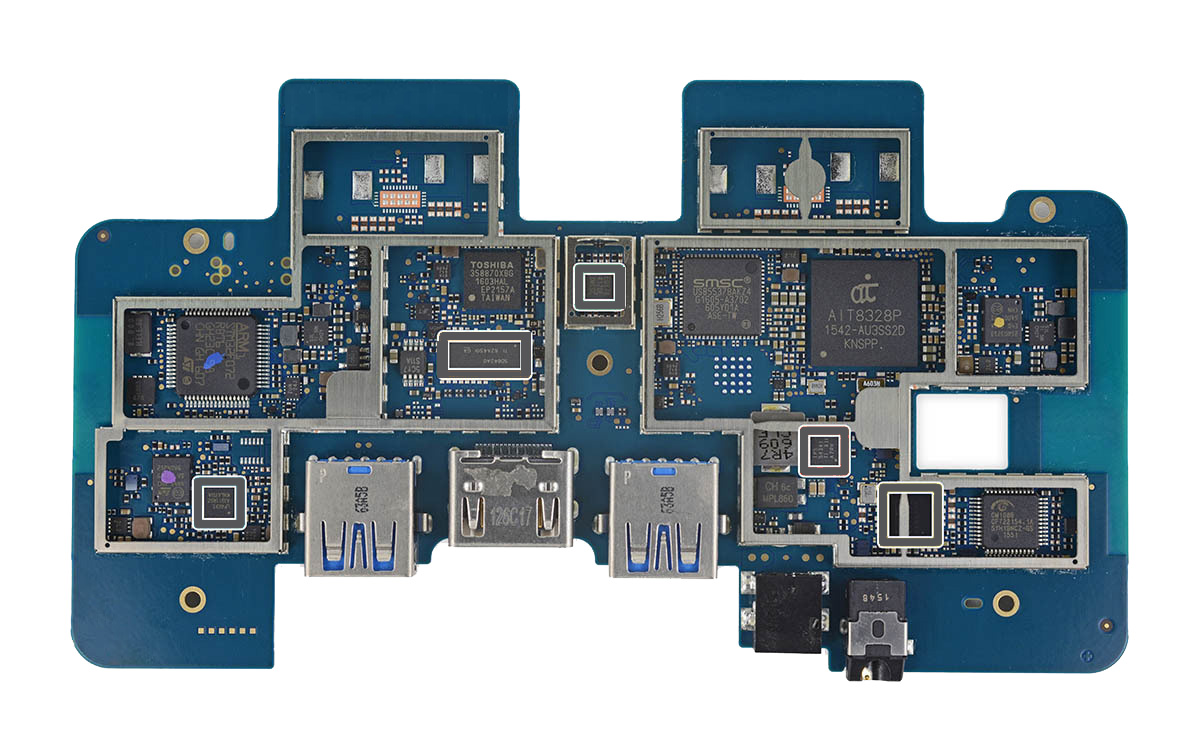

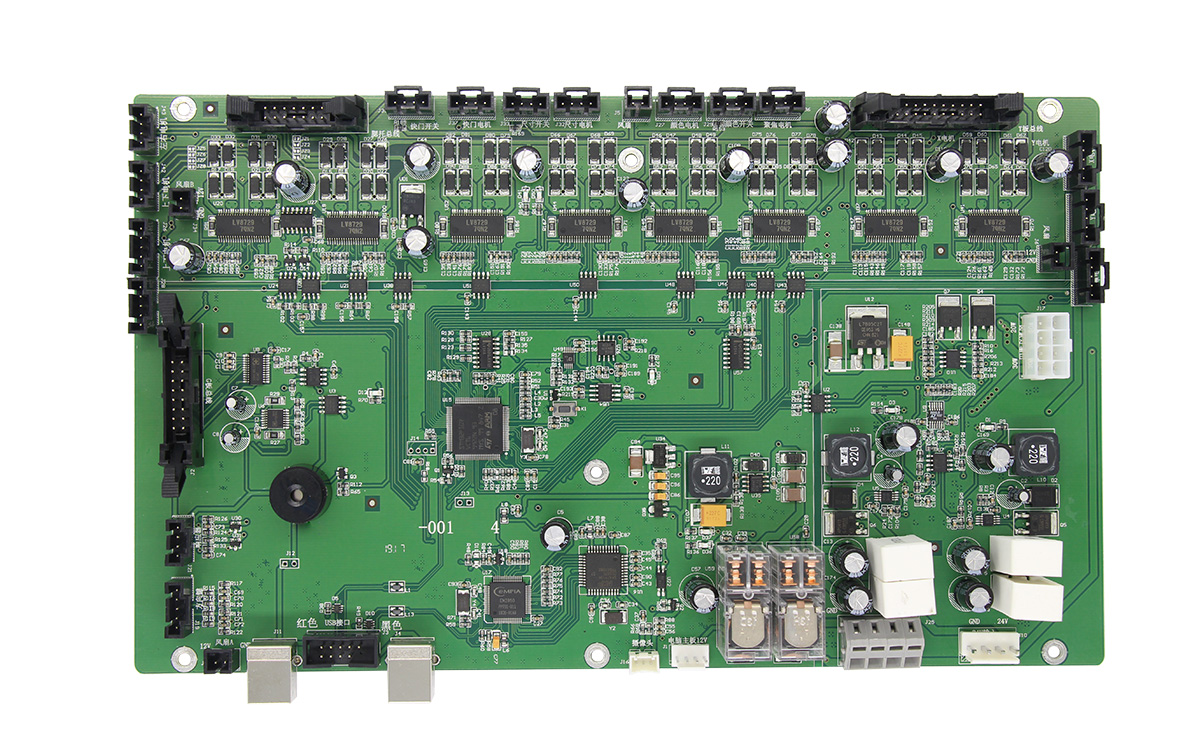

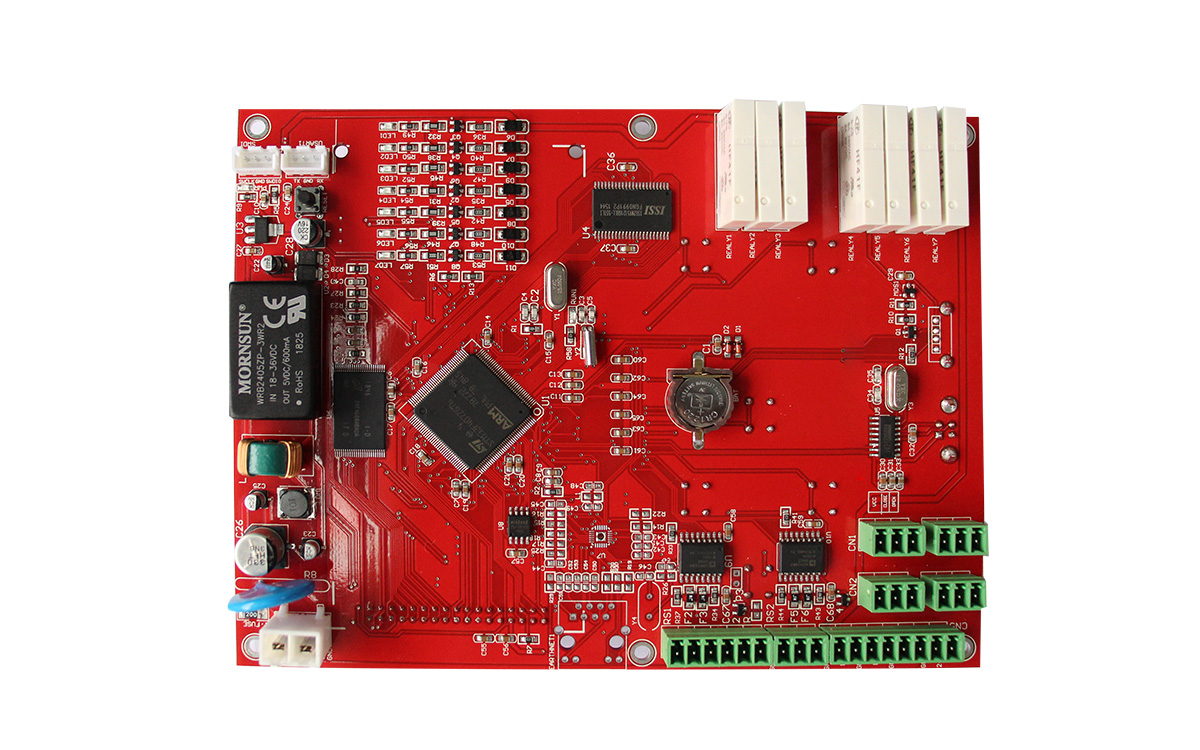

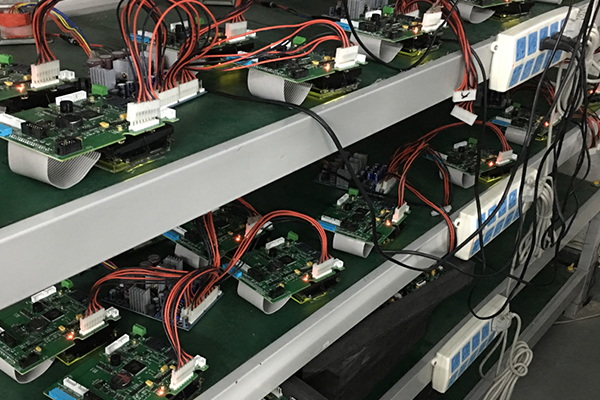

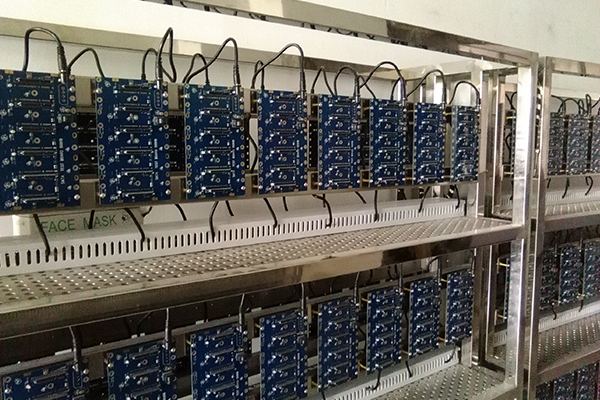

PCBA Partial Case Display

Aerospace Industry

Industrial Control Indasitiri

Consumer Electronics

Consumer Electronics

Indasitiri yezvokurapa

Automobile Industry

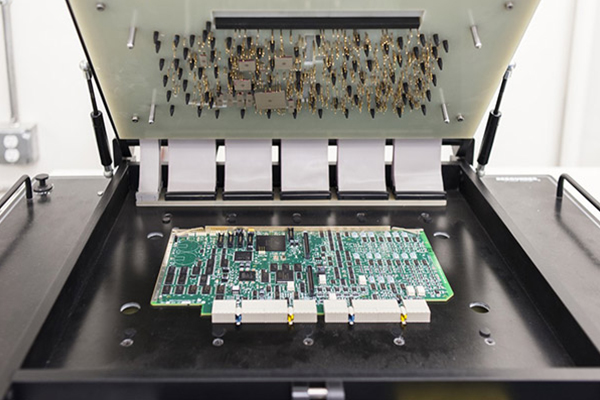

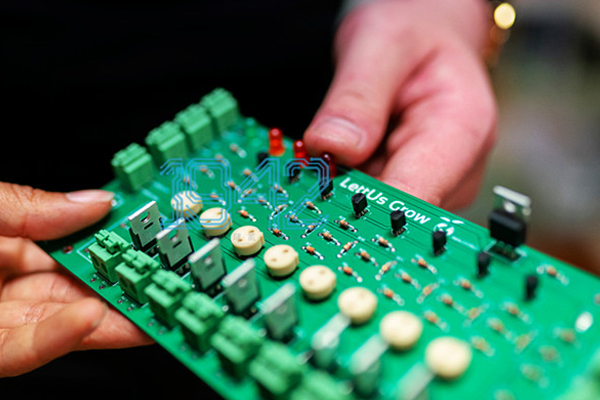

PCB bvunzo poindi inzvimbo yakakosha yakachengetwa pane yakadhindwa yedunhu bhodhi (PCB) yekuyera magetsi, kutapurirana kwechiratidzo uye kuongororwa kukanganisa.

Vatengi vanogona zvakare kugadzira nzira dzekuyedza zvinoenderana nemapoinzi ebvunzo, uye isu tichaita bvunzo zvigadziriso zvehunyanzvi zvinoshanda simulation bvunzo.

☑ Mabasa avo anosanganisira: kuyerwa kwemagetsi Nzvimbo yekuyedza inogona kushandiswa kuyera voltage, ikozvino, impedance uye mamwe maparamita emagetsi edunhu kuti ave nechokwadi chekushanda kwakajairika uye kuita kwedunhu.

☑ Chiratidzo chekufambisa:Nzvimbo yekuyedza inogona kushandiswa sepini yechiratidzo yekubatanidza nemamwe maturusi emagetsi kana kuyedza zviridzwa kuti uwane chiratidzo chekuisa uye kubuda.

☑ Kusimbisa dhizaini:

Kuburikidza nenzvimbo yekuyedza, simbisa huchokwadi uye kushanda kwePCB dhizaini kuona kuti bhodhi redunhu rinoshanda zvinoenderana nezvinodiwa zvekugadzira.

☑ Kuongororwa kwemhosva:

Kana kukanganisa kwedunhu kukaitika, unogona kutsvaga chikanganiso ichi zvichienderana nenzvimbo yekuyedza kubatsira mainjiniya kuwana chikonzero uye mhinduro yekukanganisa.

☑ Kugadzirisa nekukurumidza:

Kana zvinhu zvedunhu zvinoda kutsiviwa kana kugadziriswa, mapiidhi ebvunzo anogona kushandiswa kukurumidza kubatanidza nekubvisa maseketi, kurerutsa maitiro ekugadzirisa.