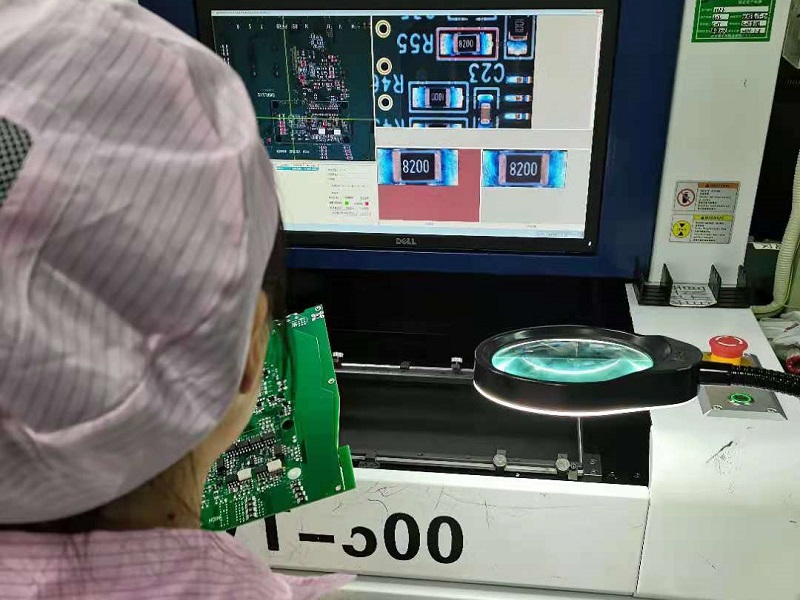

PCBA AOI (Printed Circuit Board Assembly Automated Optical Inspection) litaba tsa tlhahlobo li kenyelletsa haholo lintlha tse latelang:

1. Boemo ba karolo le polarity: Lekola hore na boemo ba karolo le polarity li kentsoe ka nepoPCB.

2. Ho haella lelikarolo tsa offset: Lekola hore na ho na le likarolo tse sieo kapa tsa offset.

3. Boleng ba welding: Lekola boleng ba welding, ho kenyelletsa hore na welding e felile, hore na li-solder li na le junifomo, ho sa tsotellehe hore na ho na le li-circuits tse khutšoanyane tsa welding kapa li-circuits tse bulehileng, joalo-joalo.

4. Boleng ba li-welding pad: Hlahloba boleng ba mochini oa welding, ho kenyelletsa le hore na mochini oa welding o felile, ho sa tsotellehe hore na ho na le oxidation, hore na ho na le potoloho e khutšoanyane kapa potoloho e bulehileng, joalo-joalo.

5. Ho kheloha ho tjheseletsa: Hlahloba hore na boemo ba welding bo kheloha litlhoko tsa moralo.

Ka ho lemoha litaba tse ka holimo, PCBA AOI e ka thusa ho netefatsa boleng le botšepehi baKopano ea PCBle ho ntlafatsa katleho ea tlhahiso le boleng ba sehlahisoa.

Nako ea poso: Mar-26-2024