PCB MOEKETSI

Re moetsi oa profeshenale oa PCB&PCBA, re fana ka PCB Produc-tion, Components Purchasing, SMT le tlhahlobo ea ts'ebetso bakeng sa lik'hamphani tsa lapeng le kantle ho naha.

E thehiloe ka 2004, re na le fektheri ea rona ea PCB le fektheri ea PCBA, re fetile ISO9001, ISO13485,TS16949,UL(E332411).

Re na le lisebelisoa tse tsoetseng pele, thekenoloji e tsoetseng pele, sehlopha se hloahloa sa tekheniki, sehlopha sa bareki, sehlopha sa QC le sehlopha sa batsamaisi. Baenjiniere ba software le ba hardware ba ka fanang ka tšehetso ea theknoloji ho bareki. tlhahiso ea morao-rao hammoho le tšehetso ea tekheniki ka mor'a ho rekisa le ho latela.

Mmaraka oa rona o moholo ke Europe, Amerika Leboea, Amerika Boroa le linaha tse ling. Lihlahisoa tse kholo li sebelisetsoa Consumer Electronics, Kopo ea Bongaka, Taolo ea Liindasteri le Toys joalo-joalo..

PCB TŠEBELETSO

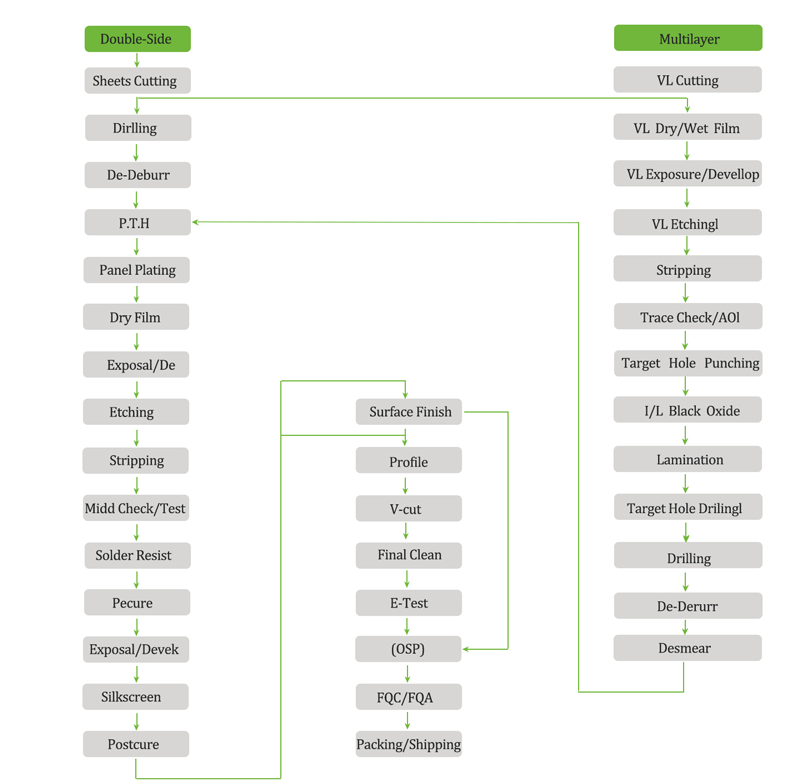

Mohala oa Tlhahiso ea PCB

Theha maemo a thata a taolo ea boleng: Theha sistimi e felletseng ea taolo ea boleng,

Tlhahlobo ea kamehla ea boleng le netefatso: Tlhahlobo ea kamehla ea boleng ba mohala oa tlhahiso e etsoa ho netefatsa hore sehlahisoa se finyella litlhoko tsa boleng le ho lekanya le ho netefatsa ho hlokahalang.

Hlahisa lisebelisoa tsa tlhahlobo tse tsoetseng pele: Sebelisa lisebelisoa tse tsoetseng pele tsa tlhahlobo, joalo ka mechini ea tlhahlobo ea X-ray, AOI (Automatic Optical Inspection), joalo-joalo, ho etsa tlhahlobo e felletseng ea li-PCB ho netefatsa boleng ba sehlahisoa.

Koetliso le thuto: Fana ka koetliso ea basebetsi le thuto e le hore ba utloisise litekanyetso le litlhoko tsa boleng ba k'hamphani le ho ba le tsebo ea ho sebetsa e tsamaellanang.

Ho lata le ho beha leihlo: Lekola le ho beha leihlo sehlopha ka seng sa li-PCB ho netefatsa botsitso le ho lateloa ha boleng ba sehlahisoa.

Kenyelletso ea Bokhoni ba PCB Craft

| The serial mumber | Ntho | Bokhoni ba ho Craft |

| 1 | Surface Finish | HASL ea mahala, khauta e qoelisoang, Plating ea Khauta, OSP, Tin ea ho qoelisoa, ho qoelisoa |

| silevera joalo-joalo. | ||

| 2 | Lera | Likarolo tse 2-30 |

| 3 | Min Line bophara | 3 mil |

| 4 | Sebaka sa Min Lime | 3 mil |

| 5 | Sebaka se senyane pakeng tsa pad to pad | 3 mil |

| 6 | Min lesoba bophara | 0.10 limilimithara |

| 7 | Min bonding pad bophara | 10 mil |

| 8 | Boholo ba karolo ea lesoba la ho phunya le | 01:12,5 |

| botenya ba boto | ||

| 9 | Boholo ba boto ea ho qetela | 23inch*35inch |

| 10 | Rang of finish baord's Thickness | 0.21-7.0mm |

| 11 | Min botenya ba soldermask | 10um |

| 12 | Soldermask | Botala, Bosehla.Bosotho, Boputsoa, Bosoeu, Bokhubelu, 'mala o bonaletsang oa sefahleho sa soldermask |

| Mask ea solder e hlobolang | ||

| 13 | Min linewidth ea Idents | 4 mil |

| 14 | Min Height of Idents | 25mil |

| 15 | 'Mala oa silika-skrine | Bosoeu, Bosehla, Botsho |

| 16 | Sebopeho sa faele ea data | GERBER FILE le DRILUNG FILE,PROTEL SERIES,PADS2000 SERIES,Powerpcb |

| ≤FR1ES.CYDB÷ | ||

| 17 | Teko ea E | Teko ea 100% E;Teko e Phahameng ea Valtage |

| 18 | Boitsebiso bakeng sa PCB | FR-4,High TG FR4,Halogen free,Rogers,CEM-1 Arlon,Taconic,PTFE,Isola jj. |

| 19 | Teko e 'ngoe | Teko ea Impedance, Teko ea Resistance, Microsection joalo-joalo |

| 20 | Tlhokahalo e khethehileng ea theknoloji | Blind & Buried Vias and High Thickness coppe |

Teko ea elektroniki ea PCB

TSIETSO TEKO

Lilemong tse 'maloa tse fetileng, tlhahlobo ea nale e fofang e fetohile mokhoa o ntseng o eketseha oa ho etsa liteko ha o bapisoa le liteko tsa PCBA tsa marang-rang ka lebaka la litlhoko tse thata tsa moralo le ho felisoa ha litšenyehelo tse phahameng tsa ho lokisa le ho etsa mananeo.

Teko ea nale e fofang ha e hloke tlhahlobo e inehetseng 'me e ka hlophisoa habonolo hore e ikamahanye le meralo le meralo e fapaneng ea PCBA, e leng ho etsa tlhahlobo ea nale e fofang e be tharollo e theko e tlase ea li-batch tse nyane le tse mahareng hammoho le kopano ea mohlala.

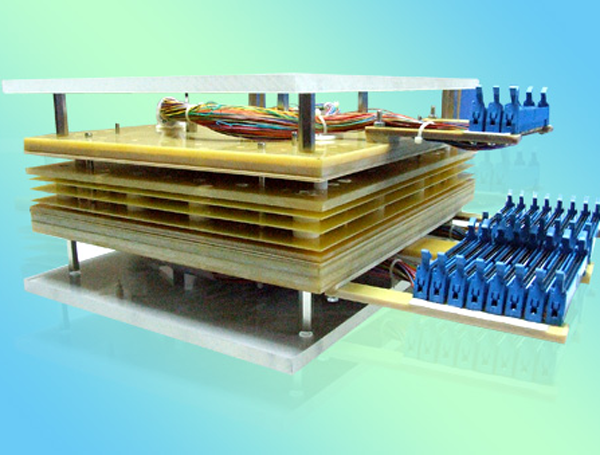

rack ea teko ea PCB

PCB batch test fixture, eo hape e bitsoang PCB test rack, ke sesebelisoa se sebelisetsoang tlhahlobo ea betch ea liboto tsa PCB.Hangata e na le likarolo tse tsitsitseng tsa boto, lithapo tse kopanyang potoloho, lithapo tsa teko, joalo-joalo Lisebelisoa tsa tlhahlobo ea batch ea PCB li sebelisoa haholo ho ntlafatsa katleho ea tlhahiso le boleng ba tlhahlobo ea liboto tsa PCB.E ka hokela mapolanka a mangata a PCB ka nako e le 'ngoe le ho etsa tlhahlobo ea lets'oao la motlakase ho liboto tsa PCB ka lithakhisa tsa liteko.U sebelisa sesebelisoa sa tlhahlobo ea batch ea PCB, qala ka ho lokisa boto ea PCB holim'a letlapa le tsitsitseng, ebe u hokela sesebelisoa ho lisebelisoa tsa tlhahlobo ka terata ea khokahano ea potoloho.

Lisebelisoa tsa tlhahlobo hangata li kenyelletsa lijenereithara tsa matšoao, li-analyzers tsa logic, multimeter, joalo-joalo. Nakong ea tlhahlobo, lisebelisoa tsa tlhahlobo li tla romela matšoao a motlakase ho lipini tsa teko tsa boto ea PCB, 'me liphetho tsa liteko li tla hlahlojoa le ho ngoloa ka lisebelisoa tse kang logic. mohlahlobi.Ka tlhahlobo ea li-batch tsa lisebelisoa, mathata a motlakase ho liboto tsa PCB a ka bonoa kapele le ka nepo, a ntlafatsa boleng ba sehlahisoa le katleho ea tlhahiso.Ka bokhutšoanyane, sesebelisoa sa tlhahlobo ea batch ea PCB ke sesebelisoa se sebetsang haholo se ka thusang liboto tsa PCB tsa liteko le ho ntlafatsa katleho ea tlhahlobo le boleng.

PHEKO

Mona ke lintlha tse ling tsa sephutheloana sa vacuum sa PCB tseo re li arolelanang le uena: