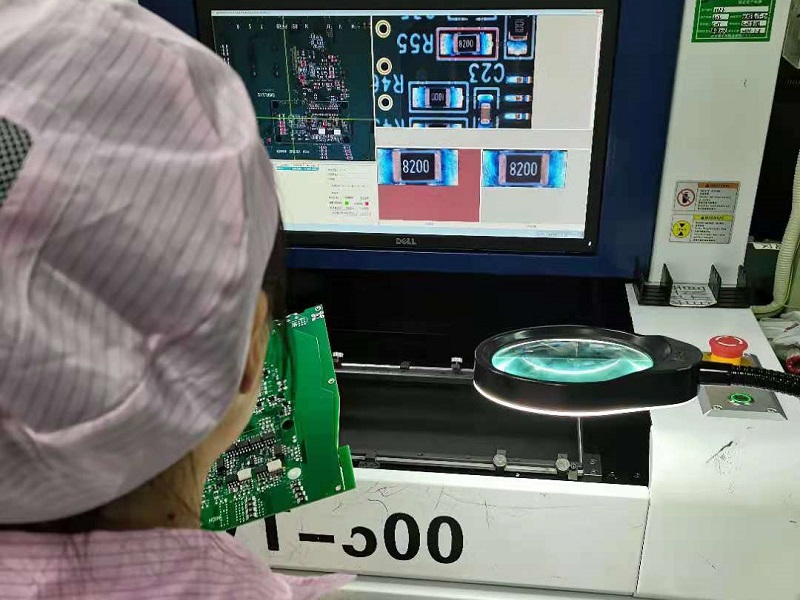

PCBA AOI (Printed Board Board Assembly Assembly Automated Optical Inspection) umxholo wokuhlola ikakhulu ubandakanya le miba ilandelayo:

1. Indawo yecandelo kunye nepolarity: Khangela ukuba indawo yecandelo kunye nepolarity zifakwe ngokuchanekileyo kwiPCB.

2. Ulahlekile kwayeamacandelo offset: Khangela ukuba kukho izinto ezingekhoyo okanye ezilungelelanisiweyo.

3. Umgangatho we-Welding: Hlola umgangatho we-welding, kubandakanywa nokuba i-welding iphelile, ingaba i-solder joints iyunifomu, ingaba kukho ii-welding short circuits okanye ii-circuits ezivulekileyo, njl.

4. Umgangatho we-welding pad: Hlola umgangatho we-welding pad, kubandakanywa nokuba i-welding pad iphelile, ingaba kukho i-oxidation, ingaba kukho isiphaluka esifutshane okanye isiphaluka esivulekileyo, njl.

5. Ukuphambuka kwe-Welding: Khangela ukuba indawo ye-welding iyaphambuka kwiimfuno zoyilo.

Ngokuchongwa kwalo mxholo ungasentla, iPCBA AOI inganceda ukuqinisekisa umgangatho kunye nokuthembeka kweIndibano yePCBkunye nokuphucula ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso.

Ixesha lokuposa: Mar-26-2024